Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

May 24 2023

May 24 2023Forged flange is a kind of product with good mechanical properties in flange products, but many people do not know how the flange works. In the face of this situation, the staff of the flange forging below will do detailed for everyone. Introduction.

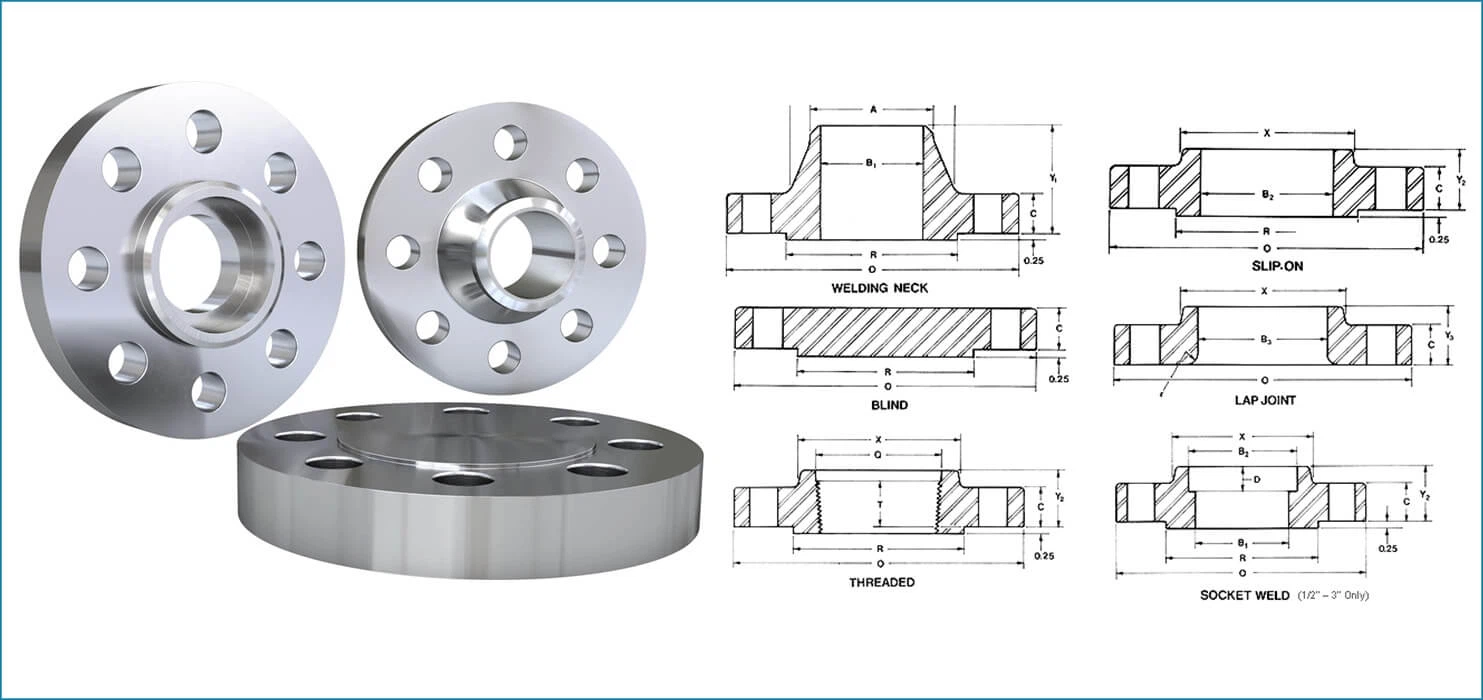

From the flange forging process, the forged flange can be cast or threaded or welded. Forging flange connection is to fix two pipes, pipe fittings or components on a flange, and between the two flanges, with flange pads, bolted together to complete the connection.

Generally speaking, forged flanges are produced on the basis of cast steel flanges, and their strength is much higher than cast steel flanges. Moreover, the forged flange is connected to the pipe end as a part capable of engaging the pipe and the pipe. There are holes in the forged flange, and the bolts make the two flanges tightly connected. Forged flanges are sealed with gaskets, and forged flanges are those with forged flanges (flanges or lands).

According to the staff engaged in forging flanges, the flange connection consists of a pair of flanges, a gasket and a number of bolts and nuts. The gasket is placed between the two flange sealing surfaces. After the nut is tightened, the specific pressure on the outer surface of the gasket reaches a certain value and then deforms, and fills the unevenness on the sealing surface, so that the joint is tight and not leaking. Forged flanges are easy to use and can accept large pressures. In industrial pipes, the use of forged flanges is very extensive. In the home, the pipe diameter is small and low pressure, and the flange connection is not visible. If it is in a boiler room or production site, there are flanges connecting the pipes and devices.

The standard forged flanges in the industry contain from 0.1% to 0.5% chromium (forged flanges usually contain no chromium), carbon content below 1.0% and forging Lan is made of high-temperature forging. Some forged flanges have a hardness (HRC) of ≥56 or more (the quenching layer is only about 15mm). Because of the poor hardenability of the forged flange material, the hardness of the core is usually more than 30. Degree, forged flanges are often treated with water quenching. Some fittings and components are now self-contained with flanges and are also flanged. Forging flange connection is an important connection method for pipeline construction.