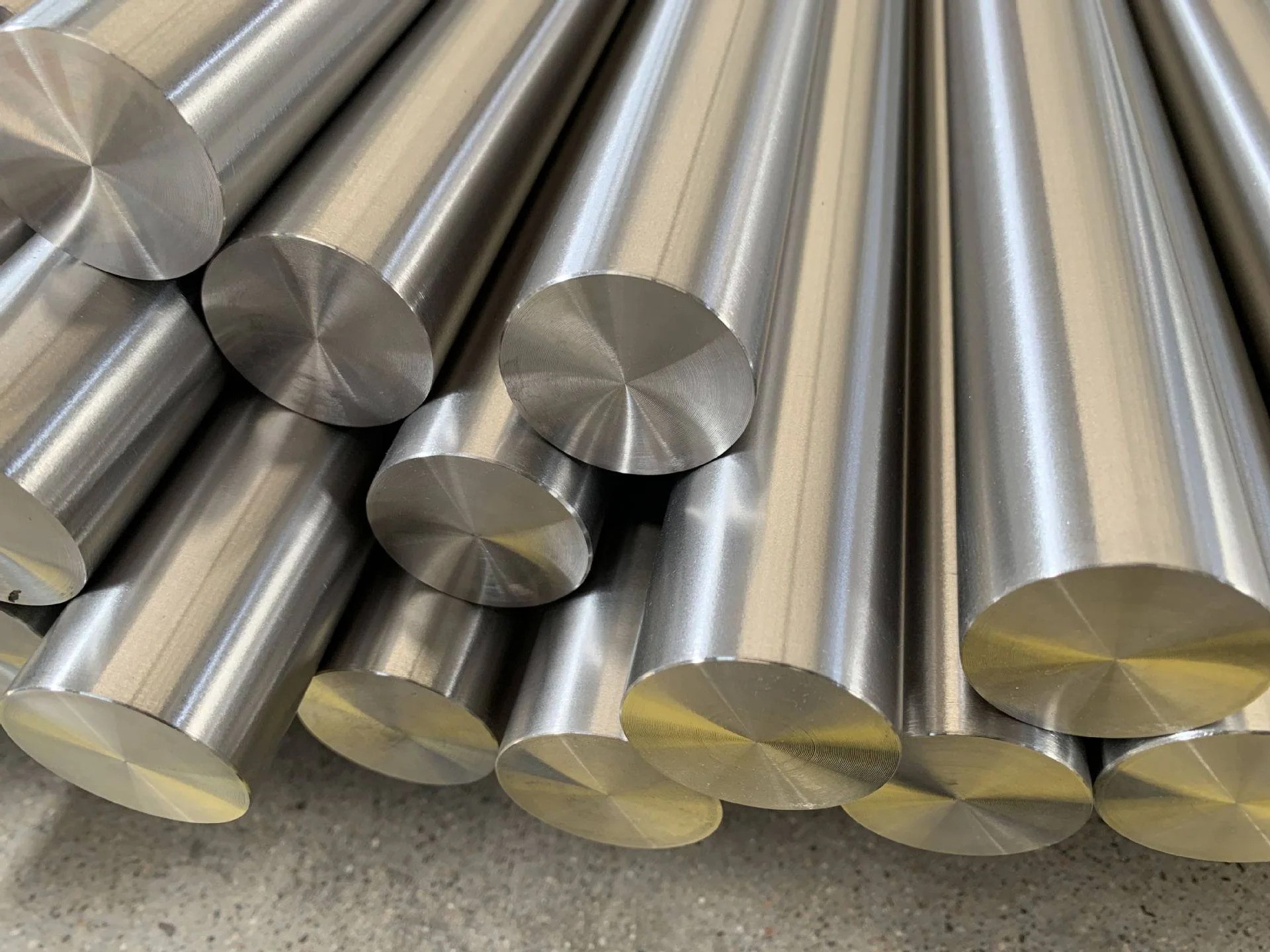

Superior Chloride Resistance: Duplex 1.4462

The exceptional performance of Duplex 1.4462 originates from its unique metallurgical structure, which consists of a balanced, nearly 50/50 microstructure of austenite and ferrite phases. This dual-phase "duplex" structure grants it a superior defense mechanism against chloride stress corrosion cracking (Cl-SCC), a common failure mode for standard 304 and 316 stainless steels in environments like seawater, chemical process streams, and saline atmospheres. With a high content of chromium, molybdenum, and nitrogen, it achieves a Pitting Resistance Equivalent Number (PREN) typically between 34-40, ensuring outstanding resistance to pitting and crevice corrosion, which are critical threats in chloride-rich settings.