Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

May 24 2023

May 24 2023Demand and production of stainless steel welded steel tubes for automobiles

In recent years, with the continuous increase of service life and exhaust temperature, automobiles have put forward higher requirements on the local corrosion resistance of the cold end of the exhaust system and the high temperature oxidation resistance of the hot end. This article reviews and analyzes the use of stainless steel welded steel pipes for automobiles against the background of increasing automobile production in my country.

1 Development of my country's auto industry and forecast of steel consumption

According to the statistical analysis of the China Association of Automobile Manufacturers, China's automobile production and sales in 2016 were 28.12 million and 28.03 million, an increase of 14.5% and 13.7% year-on-year, an increase of 11.2 percentage points and 9.0 percentage points over the previous year. new highs.

During the "Thirteenth Five-Year Plan" period, China's auto industry will continue to grow under the impetus of rigid consumer demand, auto scrapping and new energy vehicle development, but due to factors such as a large base, traffic congestion, and environmental pollution, the growth rate It will not be too high, the growth rate is predicted to be about 3%, and the output is expected to reach 31.5 million units in 2020.

As the proportion of high-strength steel used in automobiles continues to increase, the growth rate of total steel used in automobiles will be less than that of the automobile industry. In addition, auto parts exports will maintain steady growth, and the total volume of steel used for parts and repairs and maintenance consumption will increase. According to estimates, the consumption of automotive steel in 2016 was about 55.5 million tons.

In the automobile manufacturing industry, the use of stainless steel materials is increasing due to the advantages of high strength, corrosion resistance, relatively light weight, stronger energy absorption after impact than other metal materials, good safety performance, and simple manufacturing and assembly processes.

In recent years, the amount of stainless steel for each car has gradually increased from about 10kg in the 1980s to 20-30kg, and the United States has exceeded 40kg. Taken together, the annual stainless steel demand in my country's auto industry will reach about 1 million tons in the next few years

Automotive stainless steel:

2.1Application of stainless steel in automobile industry

The application of stainless steel in the automotive industry can be roughly divided into five categories: stainless steel for automobile exhaust systems, stainless steel for automobile fuel tanks, stainless steel for automobile frames, stainless steel parts for automobile and stainless steel for automobile decoration.

The stainless steel used for automobile fuel tanks is mainly stainless steel plate, which requires excellent stamping forming performance, welding performance and high corrosion resistance (internal fuel corrosion resistance and external corrosion resistance to harsh environments). Austenitic stainless steel, such as SUS304L. The stainless steel for automobile frames is a high-strength stainless steel plate for automobiles, such as an integral body shell made of ferritic stainless steel, and the service life is generally 15-20 years.

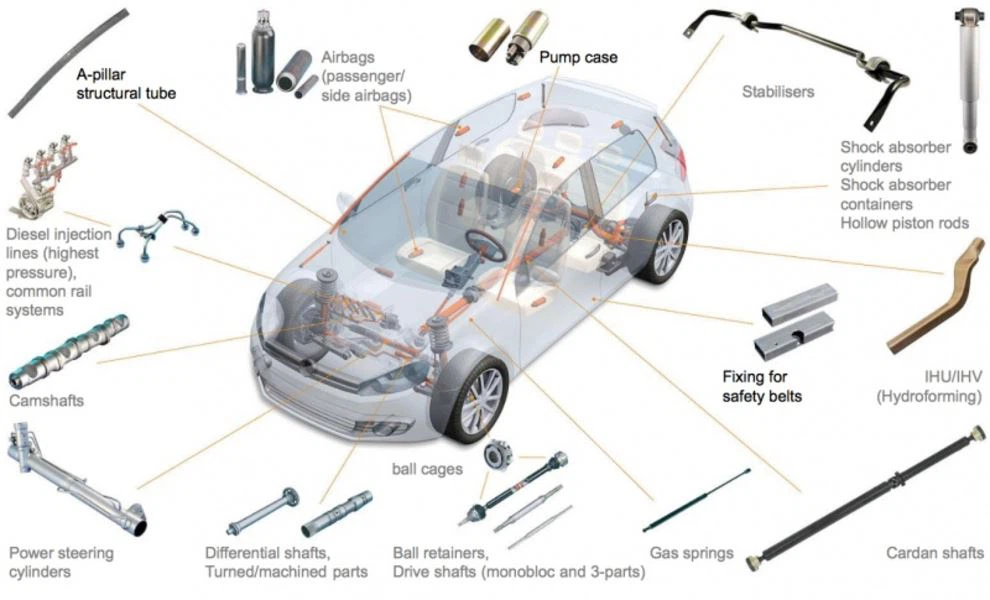

Stainless steel is also used in a variety of automotive parts, such as stainless steel seals, stainless steel plate heat exchangers (used by SUS304, SUS430, and SUS409L), stainless steel fasteners for automotive engine systems and transmission systems (usually used stainless steels are SUS410, SUS304 , SUS316, SUS430JIL, SUH660, etc.).

Automotive decoration also uses stainless steel, such as stainless steel inserts, antennas, wheel covers or handrails of large passenger cars, safety railings, boom bars, etc. Stainless steel pipes are mainly used in passenger car exhaust systems and vehicle decoration in China, of which automotive exhaust systems are mainly used.

Stainless steel welded pipe for automobile exhaust system

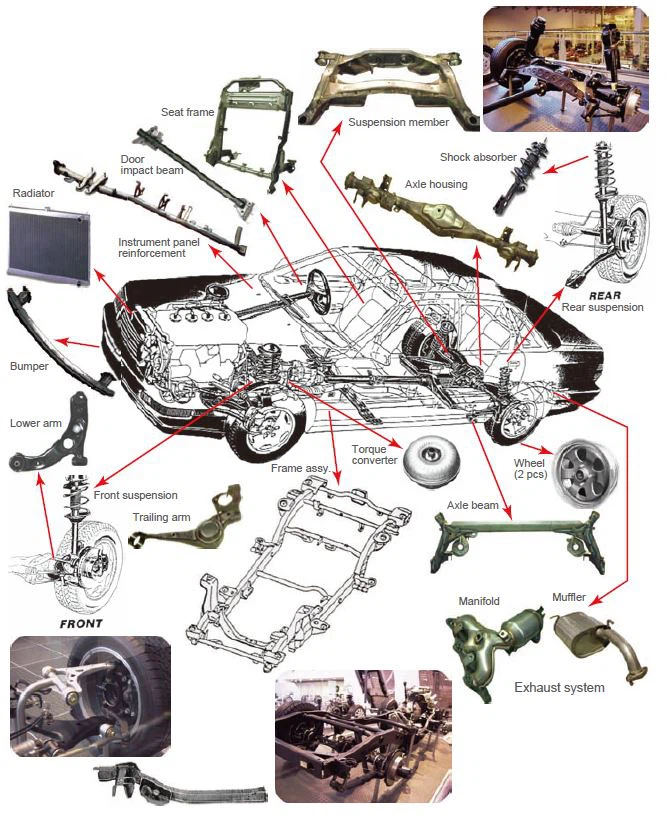

The car exhaust system is located at the bottom of the vehicle and connects the engine outlet to the atmosphere. Its main function is to discharge the exhaust gas generated by the engine, purify the exhaust gas, and reduce noise. It is related to the power, emissions, vibration noise, and comfort of the vehicle. The automobile exhaust system starts from the side close to the engine and consists of an exhaust manifold, a front pipe, a flexible pipe, a center pipe, a muffler and a tail pipe. Depending on the shape of the vehicle, some catalytic converters are also installed And vice muffler, etc.

According to the service temperature of each component of the automobile exhaust system, it is divided into the hot end of the automobile exhaust system and the cold end of the automobile exhaust system. Because the exhaust manifold is directly connected to the automobile engine and has the highest service temperature, the exhaust manifold is the representative of the hot end of the automobile exhaust system; the low service temperature of the silencer is the representative of the cold end of the automobile exhaust system.

In the composition of exhaust system components, the pipe fittings account for more than 60% of the total weight, such as the manifold, the front pipe, the center pipe, the bent pipe and the tail pipe in the muffler, etc. In the early days of automobile exhaust pipe fittings, cast iron pipes, galvanized steel pipes and aluminum-plated steel pipes were commonly used. The operating temperature of the cast iron pieces used in early exhaust manifolds was below 800°C, which could no longer meet the service conditions. At present, stainless steel thin-wall welded pipes and seamless pipes with high heat resistance have been used in the manufacture of automobile exhaust pipes.

In recent years, due to the world's energy shortages and the worsening environment, the automotive industry's demands for improving the thermal efficiency of gas and reducing the weight of the car have put forward higher requirements for the exhaust system, and constantly increasing the temperature of the engine exhaust. The exhaust manifold working temperature rises from 750℃-800℃ to 900℃-950℃, or even higher; the exhaust manifold and fasteners are converted from ordinary carbon steel to stainless steel; the exhaust gas temperature of the muffler increases, which increases the degree of corrosion , Must also use stainless steel.

At present, in the cars of Europe, the United States and Japan, the exhaust system has been used 100% stainless steel. The amount of stainless steel used in the exhaust system has accounted for more than half of the total application of automotive stainless steel. Overall, the exhaust system of each car uses about 15kg of stainless steel. From this, it is estimated that the annual use of stainless steel for the exhaust system of the automotive industry in China will be Maintained at around 500,000 tons.