Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

May 24 2023

May 24 2023The application of stainless steel in the automotive industry can be roughly divided into five categories: stainless steel for automobile exhaust systems, stainless steel for automobile fuel tanks, stainless steel for automobile frames, stainless steel parts for automobile and stainless steel for automobile decoration.

The stainless steel used for automobile fuel tanks is mainly stainless steel plate, which requires excellent stamping forming performance, welding performance and high corrosion resistance (internal fuel corrosion resistance and external corrosion resistance to harsh environments). Austenitic stainless steel, such as SUS304L. The stainless steel for automobile frames is a high-strength stainless steel plate for automobiles, such as an integral body shell made of ferritic stainless steel, and the service life is generally 15-20 years.

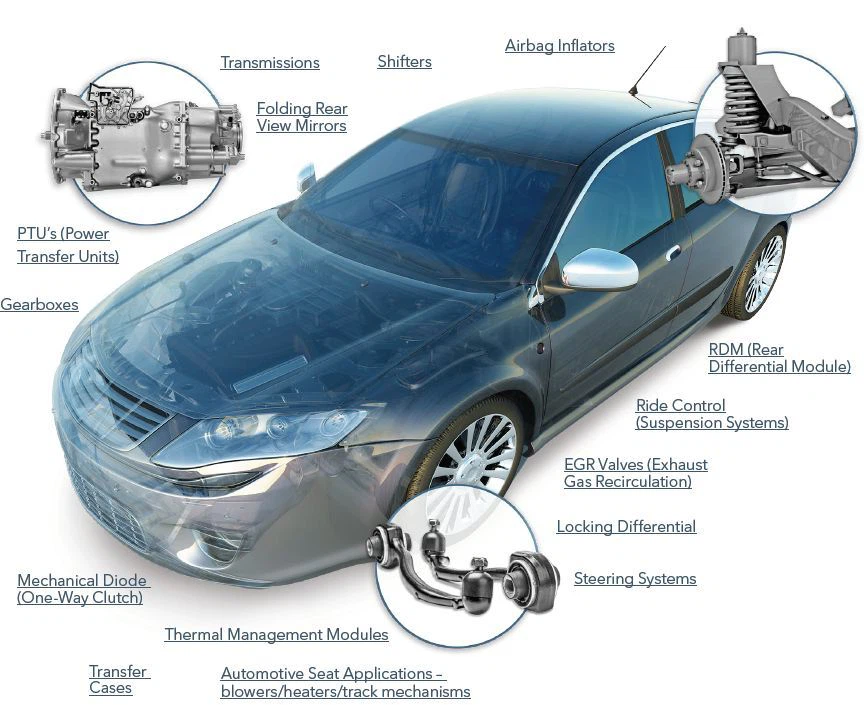

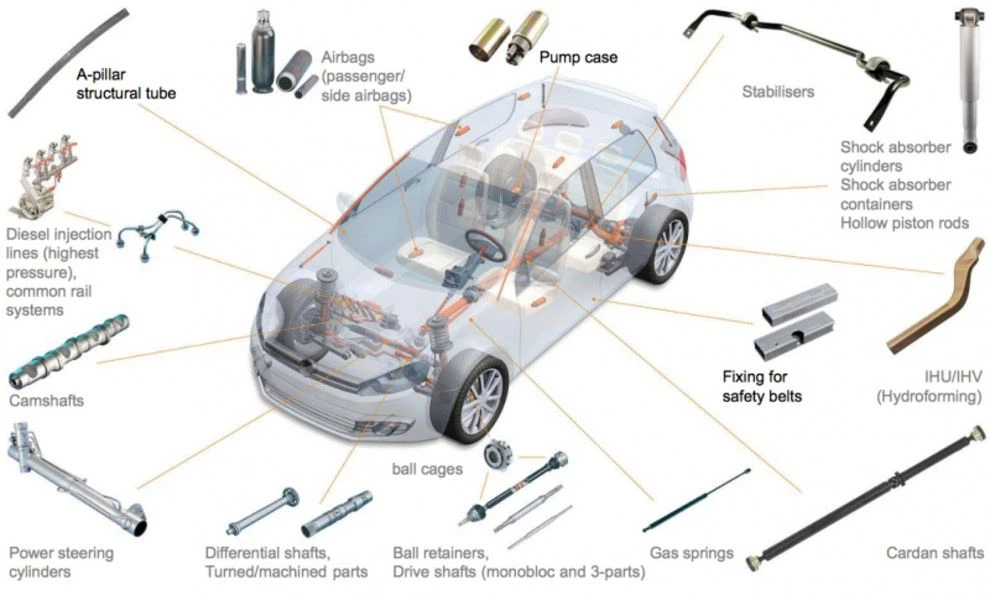

Stainless steel is also used in a variety of automotive parts, such as stainless steel seals, stainless steel plate heat exchangers (used by SUS304, SUS430, and SUS409L), stainless steel fasteners for automotive engine systems and transmission systems (usually used stainless steels are SUS410, SUS304 , SUS316, SUS430JIL, SUH660, etc.).

Automotive decoration also uses stainless steel, such as stainless steel inserts, antennas, wheel covers or handrails of large passenger cars, safety railings, boom bars, etc. Stainless steel pipes are mainly used in passenger car exhaust systems and vehicle decoration in China, of which automotive exhaust systems are mainly used.

2.2.Stainless steel welded pipe for automobile exhaust system

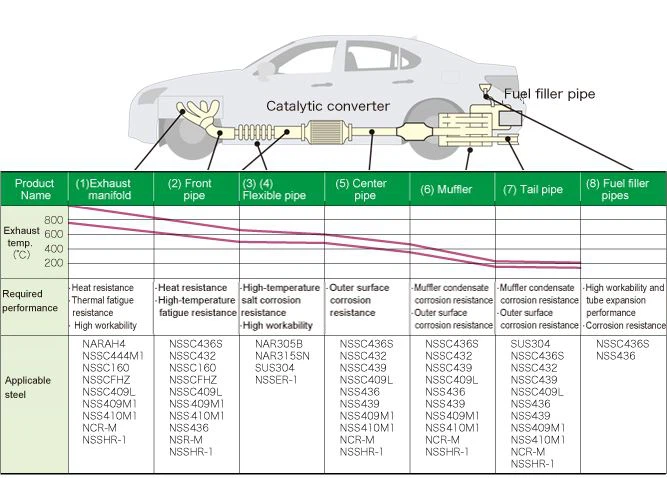

The car exhaust system is located at the bottom of the vehicle and connects the engine outlet to the atmosphere. Its main function is to discharge the exhaust gas generated by the engine, purify the exhaust gas, and reduce noise. It is related to the power, emissions, vibration noise, and comfort of the vehicle. The automobile exhaust system starts from the side close to the engine and consists of an exhaust manifold, a front pipe, a flexible pipe, a center pipe, a muffler and a tail pipe. Depending on the shape of the vehicle, some catalytic converters are also installed And vice muffler, etc.

According to the service temperature of each component of the automobile exhaust system, it is divided into the hot end of the automobile exhaust system and the cold end of the automobile exhaust system. Because the exhaust manifold is directly connected to the automobile engine and has the highest service temperature, the exhaust manifold is the representative of the hot end of the automobile exhaust system; the low service temperature of the silencer is the representative of the cold end of the automobile exhaust system.

In the composition of exhaust system components, the pipe fittings account for more than 60% of the total weight, such as the manifold, the front pipe, the center pipe, the bent pipe and the tail pipe in the muffler, etc. In the early days of automobile exhaust pipe fittings, cast iron pipes, galvanized steel pipes and aluminum-plated steel pipes were commonly used. The operating temperature of the cast iron pieces used in early exhaust manifolds was below 800°C, which could no longer meet the service conditions. At present, stainless steel thin-wall welded pipes and seamless pipes with high heat resistance have been used in the manufacture of automobile exhaust pipes.

In recent years, due to the world's energy shortages and the worsening environment, the automotive industry's demands for improving the thermal efficiency of gas and reducing the weight of the car have put forward higher requirements for the exhaust system, and constantly increasing the temperature of the engine exhaust. The exhaust manifold working temperature rises from 750℃-800℃ to 900℃-950℃, or even higher; the exhaust manifold and fasteners are converted from ordinary carbon steel to stainless steel; the exhaust gas temperature of the muffler increases, which increases the degree of corrosion , Must also use stainless steel.

At present, in the cars of Europe, the United States and Japan, the exhaust system has been used 100% stainless steel. The amount of stainless steel used in the exhaust system has accounted for more than half of the total application of automotive stainless steel. Overall, the exhaust system of each car uses about 15kg of stainless steel. From this, it is estimated that the annual use of stainless steel for the exhaust system of the automotive industry in China will be Maintain at around 500,000 tons.

3 Production of stainless steel pipes for automobile exhaust systems

3.1Process development

3.1.1 Variety of stainless steel

Since the 1970s, Japan, the United States, Europe and other countries have widely used 304 and other austenitic stainless steels for automobile exhaust systems, but the austenite stainless steel has a large linear expansion coefficient. During high temperature service, the surface oxide scale will be Significant spalling occurred, and the high cost of austenitic stainless steel gradually weakened its dominant position.

Since the 1990s, with the continuous improvement of stainless steel smelting technology, the formability and corrosion resistance of ferritic stainless steel have been significantly improved. In addition, ferritic stainless steel has been widely used in automotive exhaust systems due to its low cost, excellent corrosion resistance and high temperature characteristics, coupled with its inherent low thermal expansion rate and high thermal conductivity.

Among the stainless steels for car exhaust systems produced in my country, austenitic stainless steels are mainly 304, 309, 321, etc., and ferritic stainless steels are mainly 409, 429, 432, 436, 439, 441, 444, etc. The austenitic stainless steel used in the exhaust system has been domestically produced; ferritic stainless steel has fewer brands, its performance is not as stable as foreign products, and the user's habits, etc., the most used materials are imported from Japan, South Korea, 409, 439, 436 and other materials. . Due to its relatively low price, 409L has been widely used in automobiles as the main steel grade for automotive exhaust systems.

Due to the different environments of automotive exhaust system components, the performance requirements of materials vary. For example, the hot end mainly focuses on the high-temperature oxidation and high-temperature fatigue properties of the material, and mainly selects SUS429 and SUS441 with excellent high-temperature resistance. Condensate corrosion is the main form of failure in cold end parts such as mufflers. Condensate corrosion resistance and formability should be considered when selecting materials. Low-chromium SUH409L and medium-chromium SUS439L, SUS436L and other steel grades are preferred. Choose ferrite stainless steel and molybdenum-containing stainless steel with good resistance to high-temperature oxidation and high-temperature salt corrosion, such as SUH409L and B436L.

At present, in the Japanese automobile manufacturing industry, stainless steel for exhaust manifolds of cars is made of SUH409L; the stainless steel used in the exhaust system of the American automobile manufacturing industry is T409, T439, AL409, 436S, etc. As the exhaust temperature rises, the trend of the stainless steel for exhaust manifolds from SUH409L (low grade) and SUS430JIL (high grade) to the high-performance material SUS444 gradually becomes obvious.

The stainless steel of the automobile exhaust system has been basically realized, but in the future, materials with higher performance and lower prices will be used. With the further improvement and perfection of production technology, the application of ferritic stainless steel will become more and more extensive.

3.1.2 Production process

The pipes used for automobile exhaust system parts are stainless steel welded pipes obtained by cold-rolled sheet bending and welding, and also processed into different shapes of pipe by cold-forming and welding processes such as bending, necking and expanding. Therefore, the welded pipe is required to have good formability and welding performance.

Most of the stainless steel welded pipes used in automobile exhaust systems are below 2.5mm. The production mainly uses continuous forming straight seam welding methods, including tungsten arc welding (TIG), high frequency resistance welding (HFW), laser welding (LBW) and their Combination welding between (HFW+LBW), etc. For the use of stainless steel welded pipes with a high proportion, early welding mainly used argon arc welding (TIG). With the wide application of high-frequency welding (HFW) and laser welding (LBW) processes, in Europe, America and Japan, high-efficiency high-frequency welding and laser welding modes have been used in automotive stainless steel welded pipes.

In my country, due to factors such as large investment in equipment and high welding process requirements for laser welding and high-frequency welding, TIG welding is still the main welding process in major welded pipe factories. In recent years, with the rapid development of my country's auto industry, the supporting auto parts general contractors and their secondary suppliers have also recognized the significant advantages of high-frequency welding and laser welding processes. In order to meet the needs of production and use, some welded pipe enterprises have turned the newly added welded pipe production line to laser and high-frequency welding processes.