Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

May 24 2023

May 24 2023Stainless-steel tubingmaterial When selecting stainless steel tubes material, a choice you might require to make is whether your task must utilize Semless or Weleded as well as drawn tubes.

For decades, all stainless-steel tubes were smooth. Nonetheless, advancements in welding and steel purification innovations have triggered the popularity of welded tubing.

What Is Seamless Stainless Steel Tubes and also What Are the Advantages?

stainless steel smooth tubing Seamless tubing has no longitudinal weld joint. The manufacturing of seamless tubing needs a system to compel the hole into the billet.

Rotating piercing and rolling is one of the most common method for generating smooth tubes today. The process begins with a conditioned steel round bar, which is heated, pierced, and also worked. The bar is made to stream around a piercer factor in order to form a hollow billet.

The interior of the tube is sustained with a mandrel or a plug while the billet roller is lengthened. Sizing of the steel tube is attained by extra rolling on the outside diameter.

Seamless tubing has 20% greater ASME (American Society of Mechanical Engineers) functioning pressures contrasted to Weleded tubes of the very same product and also dimension because of having actually no welded joint. The Weleded and also attracted tubing can likewise have a noticeable joint that may worry end users.Another advantage of smooth tubing is that it can provide superior

corrosion resistance due to the fact that it has little capacity for contaminations. Utilizing smooth tubing enables you to prevent the potential for flaws and distinctions in pliability that might be

associated with the Weleded area in Weleded tubes. Unlike welded tubes, smooth tubes do not call for testing for weld stability.

Samless tubing is commonly a lot more ideal for vital applications.

What Is Welded Stainless-steel Tubes as well as What Are the Advantages?

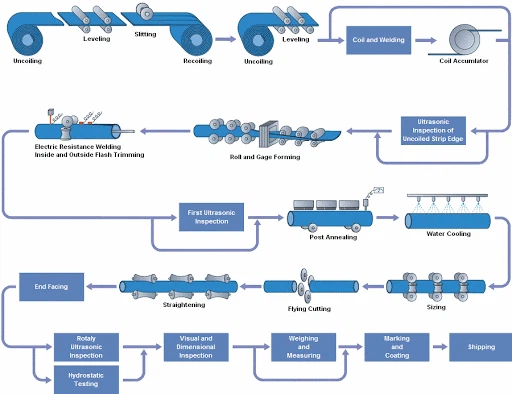

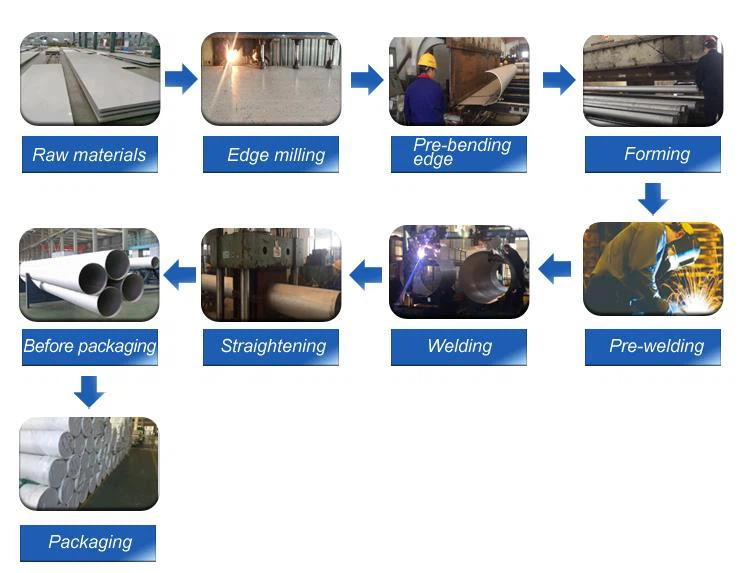

Weleded stainless steel tubingThe welded tubing manufacturing process begins with the rolling of a steel coil to the desired scale density.

The result is a coil of a level strip. The next action involves cutting the strip according to the size that refers the size of television to be created.

The tube is developed by moving the cut coil with a series of rollers, as well as the seam of television is after that Weleded in a chemically neutral setting. A rolling application is made use of to build the

welded seam, as well as a warmth treating process is used to complete the welded tube. Weleded tubes can after that be attracted over mandrels and ground if needed to smooth the welded joint as well as make it virtually impossible to see with the naked eye.

Weleded as well as drawn tubing,Because less drawing and annealing are needed in the manufacture of a welded as well as attracted tube, the expense of welded and attracted tubing can be less expensive than seamless tubing as well as can normally be obtained quicker than seamless tubing (although equipping of intermediate dimension beginning supply for seamless tubes can decrease this lead time as well).

Welded Stainless Steel Pipe ManufactuerProcessing

Both Welded and semaless Tubing Need to Fulfill Stress Requirements ASTM A269 is the ASTM International basic spec for smooth and also welded austenitic stainless-steel tubing for basic solution. The basic requires conformation to its chemical make-up requirements and information the hardness demands for various grades of tubes.

ASTM A269 likewise needs a non-destructive electrical examination or a hydrostatic examination for pressure testing all smooth and also welded tubing. The typical consists of the tensile stress restrictions for tubes of variable outside sizes and also wall surface densities.

There are several other ASTM standards that can be related to Smooth or Welded and Drawn stainless steel tubes. Please see our post on ASTM Requirements.

Should You Choose Welded or Seamless Stainless-steel Tubing?

Stainless-steel tubing,When picking welded or seamless tubes, it should be certified with your task specs. You must take into consideration the problems in which the tubes will ultimately be made use of if the specifications do not require a specific type of tubing. Another element to take into consideration is that seamless can be substituted for Weleded tubes however welded tubes might not have the ability to be replacemented for smooth as a result of the weld joint. The chart below is a fast recommendation to help you in your decision making procedure:

|

Comparison of Welded/Drawn Seamless Tubing |

||

|

|

Welded and Drawn |

Seamless |

|

Lead Time |

X |

X |

|

Tolerances |

X |

|

|

Concentricity |

X |

|

|

Cost |

X |

|

|

Availability |

X |

X |

|

High Pressure |

|

X |

|

ID Surface |

|

X |

|

Heavy Wall |

|

X |

|

Substitution |

|

X |

Stainless Steel Pipesare usually transported by two special techniques, which produce welded or seamless pipes. Both seamless steel pipe and welded pipe are mainly different in the forming process. and seamless Pipe & Welded Pipe are both widely used with Industry. Ronsco Has 23+ years experices Supply Stainless Steel. Specializing in steel pipes and steel pipe applications. We offer a broad range of customized pipe and tube products and services using a worldwide network of stock-keeping branches. Every day, our employees apply their specialist knowledge of sourcing, project management, logistics and stock planning on behalf of customers in the Industry and Energy markets.