Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

Dec 16 2024

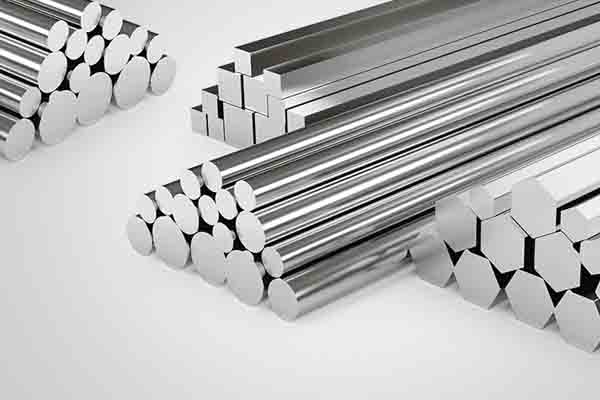

Dec 16 2024Have you ever pondered over those gleaming, polished metal bars adorning diverse industrial landscapes? These are none other than bright bars, pivotal components across various sectors. These intricately crafted metal items boast a unique allure and outstanding functionality, rendering them essential across a myriad of uses. Whether enhancing a high-powered engine, sculpting furniture, or innovating medical devices, bright bars often hold the solution for success. Join us as we delve into the world of bright bars, unraveling their essence, production intricacies, diverse variants, practical scenarios, and versatile applications.

What are Bright Bars? Bright Bars, distinguished by their sleek, reflective surface, represent a specialized category of metal bars renowned for their impeccable dimensional precision, stringent tolerances, and superior mechanical attributes. Unlike conventional metal bars like hot-rolled or cold-rolled variants, bright bars undergo a unique manufacturing procedure that imparts them with a distinctive luster and exacting measurements. Noteworthy for their consistent surface finish, premium material composition, and precise dimensional accuracy, bright bars stand out as the preferred option for endeavors prioritizing precision and aesthetic appeal.

How are bright bar produced? The manufacturing process of bright bars is a meticulous sequence of steps aimed at ensuring top-quality and consistency. It begins with selecting the appropriate material, typically steel but potentially aluminum, copper, or stainless steel based on the application, where the raw material's chemical composition and purity are pivotal. Subsequently, the process involves either hot rolling, heating the metal and shaping it with rollers, or cold drawing, pulling the metal through dies for dimensioning without heat. Following shaping, grinding or polishing eliminates imperfections, giving bright bars their renowned mirror-like finish. Rigorous quality control measures are integral throughout, with manufacturers employing stringent testing to meet industry standards.

Do you know the common types of bright bars? Bright Bars come in various shapes tailored for specific applications. Bright Round Bars, the classic cylindrical variant, find extensive use in machinery, automotive parts, and construction components, offering versatility in diameters and lengths. Bright Square Bars, with a square cross-section, excel in resisting rolling and twisting forces, ideal for stability in structural components, machine frames, and heavy equipment. Bright Hex Bars, featuring a hexagonal shape, are prized in construction, automotive, and engineering sectors for enhanced stability and load-bearing capacities. The selection of bright bar type hinges on application specifics like strength, corrosion resistance, or aesthetics. Ronsco provide a diverse array of bright bars to meet a spectrum of requirements, ensuring the perfect fit for each project.

What are the uses of bright bar? Bright bars find extensive applications across various industries owing to their superior surface finish, dimensional precision, and mechanical attributes. In the automotive sector, they play a vital role in crafting engine components, steering systems, and suspension parts, ensuring operational smoothness and reliability. Within aerospace and defense, bright bars are indispensable for producing aircraft parts and missile components, where quality and reliability are paramount. In construction and engineering, these bars are integral for fabricating machinery, tools, and structural elements due to their strength and dimensional consistency. The medical field relies on bright bars for manufacturing surgical instruments, prosthetics, and specialized equipment, benefitting from their cleanliness, precision, and corrosion resistance. Additionally, in furniture and interior design, the polished appearance of bright bars imparts elegance and sophistication to products ranging from high-end furnishings to architectural fittings.

In conclusion, Bright bars stand as indispensable metal components across various industries, playing a pivotal role in numerous applications. The manufacturing of these bars entails a specialized process encompassing meticulous material selection, advanced production techniques, and stringent quality controls. For high-quality bright bars, Ronsco emerges as a premier choice. Renowned for top-notch products meeting stringent industry benchmarks, Ronsco, a leading bright bar manufacturer, offers a diverse range of materials, shapes, and sizes to cater to all project requirements. Reach out today to explore how Ronsco's expertise can elevate your projects with precision-crafted bright bars.