Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

|

RONSCO Stainless Steel Square Bar Data Sheet |

|

| Product Name |

316/316L Stainless Steel Square Bars/Rods - SS Square Bar |

| Equivalent Materials |

316: UNS S31600/DIN 1.4401/AISI 316/SAE 316/SUS316/06Cr17Ni12Mo2 316L:UNS S31603/EN 1.4404/AISI 316L/SAE 316L/SUS316L/022Cr17Ni12Mo2 |

| Type | Cold drawn, hot rolled, forged |

| Shape | Square Bars, Square Rods |

| Standard | GB,AISI,ASTM,DIN,EN,JIS |

|

Available Grades |

Stainless steel 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 32760 / 253MA / 254SMo / XM-19 / S31803 / S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65 etc |

| Monel 400 / Monel K-500 | |

| Inconel 600 / Inconel 601 / Inconel 625 / Inconel 617 / Inconel 690 / Inconel 718 / Inconel X-750 | |

| Incoloy A-286 / Incoloy 800 / Incoloy 800H / Incoloy 800HT | |

| Incoloy 825 / Incoloy 901 / Incoloy 925 / Incoloy 926 | |

| Nimonic 75 / Nimonic 80A / Nimonic 90 / Nimonic 105 / Nimonic C263 / L-605 | |

| Hastelloy B / Hastelloy B-2 / Hastelloy B-3 / Hastelloy C / Hastelloy C-276 / Hastelloy C-22 | |

| Hastelloy C-4 / Hastelloy C-2000 / Hastelloy G-35 / Hastelloy X / Hastelloy N | |

| PH stainless steel 15-5PH / 17-4PH / 17-7PH | |

| Finish | bright, pickling, polished, |

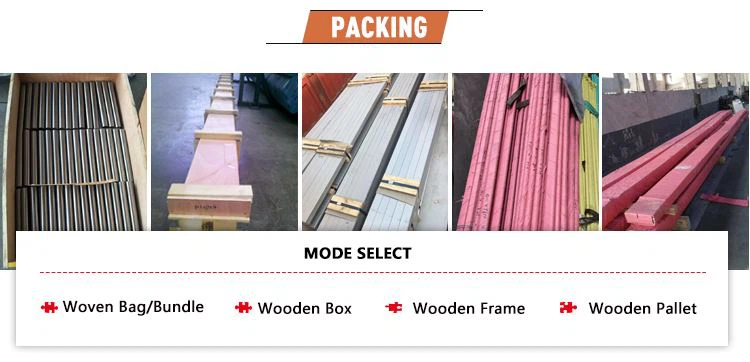

| Packing | wooden box, waterproof polybag |

| Inspection | TUV,BV,ABS,LR and so on |

| Application | Construction, shipbuilding, Chemical, Pharmaceutical & Bio-Medical, Petrochemical & Refinery, Environmental, Food Processing, Aviation, Chemical Fertilizer, Sewage Disposal, Desalination, Waste Incineration etc. |

| Processing Service | Machining : Turning / Milling / Planing / Drilling / Boring / Grinding / Gear Cutting / CNC Machining |

| Deformation processing : Bending / Cutting / Rolling / Stamping | |

| Welded | |

| Forged | |

| Delivery Time | 7-40 days |

| Trade Term | FOB CIF CFR CIP DAP DDP EXW |

| Payment | T/T, L/C,D/A,D/P, Western Union,MoneyGram,According to customer requirements payments for offline orders. |

| Transportation | By air, by sea, by train, by truck |

| Sample | Free |

| Warranty | Trade assurance after sales service |

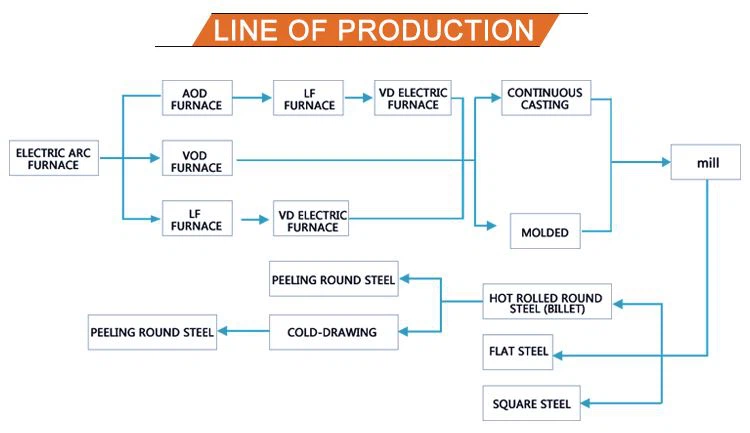

1. The raw materials are smelted by ourselves and the raw materials are all from large factories

2. It can roll 100 tons per day and keep regular stocks

3. Fast delivery, 7-15 days

4. Material processing can be done according to customer requirements

For more information about 316/316L Stainless Steel Square Bars/Rods, please call +86 17708476248 or send an Email to [marketing@ronsteel.com]