Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

Alloy C276 is a nickel-molybdenum-chromium superalloy with an addition of tungsten designed to have excellent corrosion resistance in a wide range of severe environments. The high nickel and molybdenum contents make the nickel steel alloy especially resistant to pitting and crevice corrosion in reducing environments while chromium conveys resistance to oxidizing media. The low carbon content minimizes carbide precipitation during welding to maintain corrosion resistance in as-welded structures. This nickel alloy is resistant to the formation of grain boundary precipitates in the weld heat-affected zone, thus making it suitable for most chemical process application in an as welded condition.

Although there are several variations of the Hastelloy nickel alloy, Alloy C-276 is by far the most widely used.

Alloy C-276 is widely used in the most severe environments such as chemical processing, pollution control, pulp and paper production, industrial and municipal waste treatment, and recovery of sour natural gas.

Corrosion Resistant Alloy C276

Considered one of the most versatile corrosion resistant alloys available, Alloy C-276 exhibits excellent resistance in a wide variety of chemical process environments including those with ferric and cupric chlorides, hot contaminated organic and inorganic media, chlorine, formic and acetic acids, acetic anhydride, seawater, brine and hypochlorite and chlorine dioxide solutions. In addition, alloy C-276 resists formation of grain boundary precipitates in the weld heat affected zone making it useful for most chemical processes in the as-welded condition. This alloy has excellent resistance to pitting and stress corrosion cracking.

What are the characteristics of Alloy C276?

Excellent corrosion resistance in reducing environments

Exceptional resistance to strong solutions of oxidizing salts, such as ferric and cupric chlorides

High nickel and molybdenum contents providing good corrosion resistance in reducing environments

Low carbon content which minimizes grain-boundary carbide precipitation during welding to maintain resistance to corrosion in heat-affected zones of welded joints

Resistance to localized corrosion such as pitting and stress-corrosion cracking

One of few materials to withstand the corrosive effects of wet chlorine gas, hypochlorite and chlorine dioxide

Chemical Composition, %

|

Ni |

Mo |

Cr |

Fe |

W |

Co |

Mn |

C |

V |

P |

S |

Si |

|

Remainder |

15.0-17.0 |

14.5-16.5 |

4.0-7.0 |

3.0-4.5 |

2.5 max |

1.0 max |

.01 max |

.35 max |

.04 max |

.03 max |

.08 max |

The applications of Alloy C-276

Pollution control stack liners, ducts, dampers, scrubbers, stack-gas reheaters, fans and fan housings

Flue gas desulfurization systems

Chemical processing components like heat exchangers, reaction vessels, evaporators, and transfer piping

Sour gas wells

Pulp and paper production

Waste treatment

Pharmaceutical and food processing equipment

Fabrication with Alloy C-276

Alloy C-276 alloy can be forged, hot-upset and impact extruded. Although the alloy tends to work-harden, you can have it successfully spun, deep-drawn, press formed or punched. All of the common methods of welding can be used, although the oxyacetylene and submerged arc processes are not recommended when the fabricated item is for use in corrosion service.

ASTM Specifications

|

Pipe Smls |

Pipe Welded |

Tube Smls |

Tube Welded |

Sheet/Plate |

Bar |

Forging |

Fitting |

Wire |

|

B622 |

B619 |

B622 |

B626 |

B575 |

B574 |

B564 |

B366 |

|

Mechanical Properties

Typical Room Temperature Tensile Properties of Annealed Material

|

Product Form |

Tensile (ksi) |

.2% Yield (ksi) |

Elongation % |

|

Bar |

110.0 |

52.6 |

62 |

|

Plate |

107.4 |

50.3 |

67 |

|

Sheet |

115.5 |

54.6 |

60 |

|

Tube & Pipe |

105.4 |

45.4 |

70 |

Product Details:

|

Product Name: |

Alloy c276 pipe |

|

|

Material: |

Alloy c276 UNS N09901 ; DIN W.Nr.2.4819 |

|

|

Specification: |

Wire: 0.01-10mm |

|

|

Standard: |

GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

|

|

Inspection: |

ISO, SGS, BV, and so on. |

|

|

Product |

1. According to the preparation process can be divided into deformation superalloys, |

|

|

Application: |

High-temperature components such as turbine blades, guide vanes, turbine disks, high pressure |

|

|

Delivery: |

7-25days or according to the product |

|

|

Payment: |

L/C,D/A,D/P,T/T,Western Union,MoneyGram,According to customer requirements payments for offline orders. |

|

Execution standard:

|

Product |

ASTM |

|

Bar & Profile |

ASTM B446 |

|

Thick Plate, Sheet & Strip |

ASTM B443 |

|

Seamless pipe |

ASTM B444 |

|

Welded nominal pipe |

ASTM B704 |

|

Seamless & Welded pipe fittings |

ASTM B704 |

|

Forgings |

ASTM B564 |

The minimum value of mechanical properties of alloys at the normal temperature:

|

Alloy States |

Tensile Strength |

Yield Strength |

Elongation |

Hardness |

|

RM N/mm² |

RP0.2N/mm² |

A5 % |

HB |

|

|

Sheet & Strip |

≥827 |

≥414 |

≥30 |

≤220 |

|

Plate |

≥827 |

≥414 |

≥30 |

≤220 |

|

Bar |

≥827 |

≥414 |

≥30 |

≤220 |

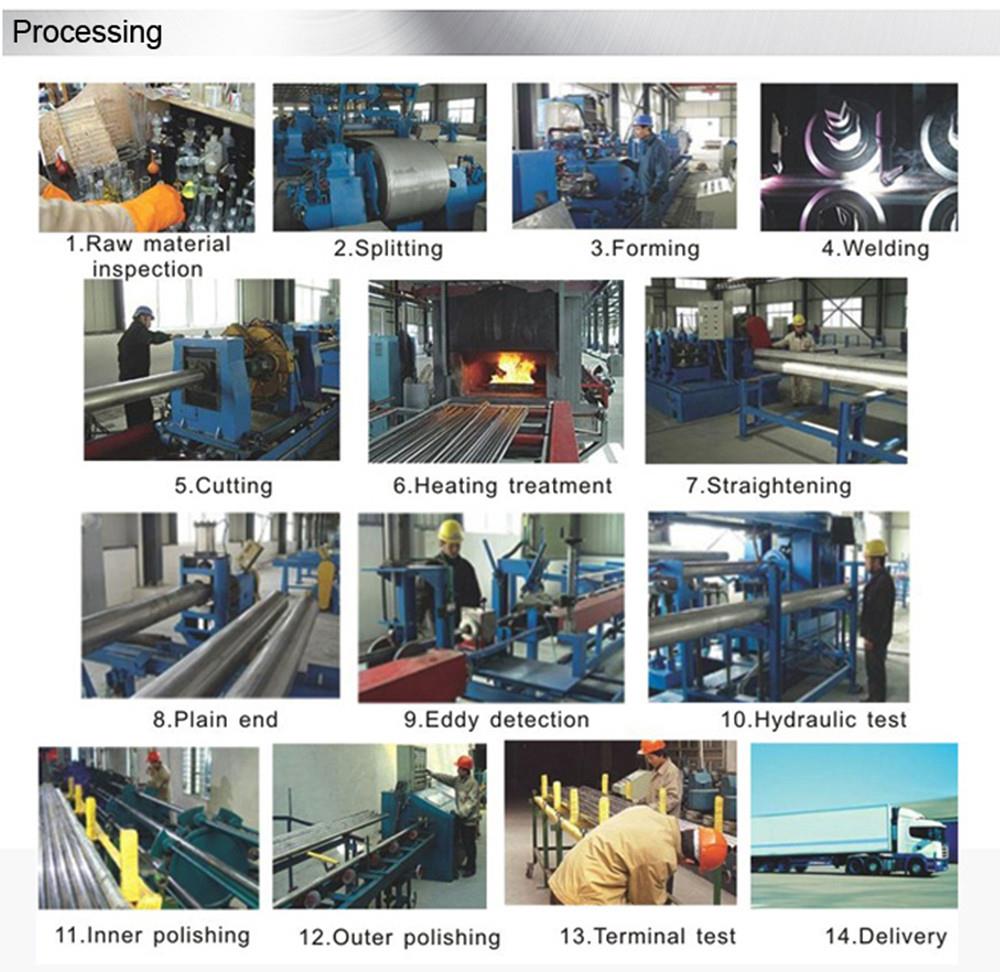

Production Process

Our high-temperature alloy production base is in Jiangsu (Suzhou) province, and our factory has 168 employees and 12 technicians. The main products are bars, tubes, and forgings, and the main material is 254SMO / 253MA/ XM-19 / Inconel 625 / Inconel 718 / Alloy C276 / Incoloy A-286 / Monel 400 / Monel K-500.

Our raw materials are mainly from Jinchuan, whose nickel output ranks third in the world. We are the strategic partner of Jinchuan group nickel alloy co., LTD.

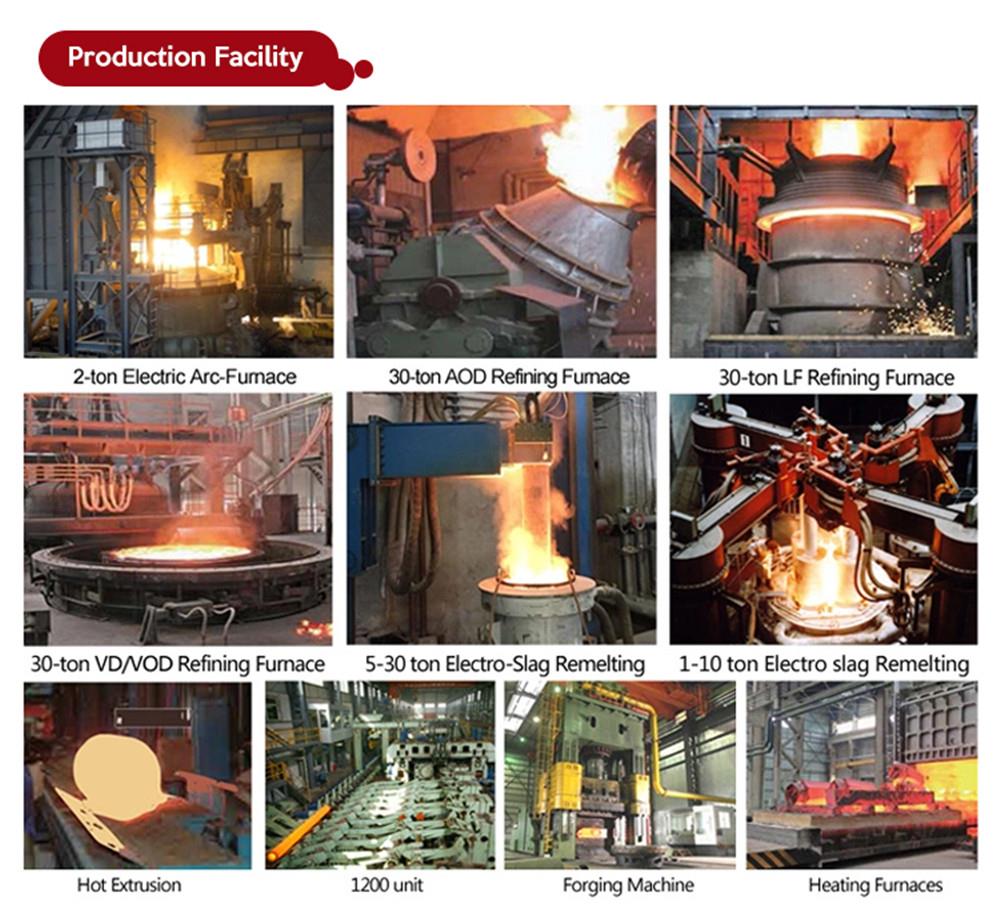

At present, the company has 1.5 tons of VIM vacuum induction furnace, 1-5 tons of electro-slag remelting furnace and hydrogen atmosphere protection electro-slag ingot furnace, a full set of 20 tons of electric furnace, AOD refining furnace, LF ladle refining furnace, VD vacuum furnace, 5 tons of forging hammer and 8 mn fast forging machine, etc..

Available Shape of High-temperature alloy steel

Application area:

High temperature alloy are widely used in petroleum chemistry, electric power, machinery manufacturing, automobile manufacturing, aerospace, offshore drilling, military and other industrial fields.

Production Facility

Testing Equipment

Optin 1: packed with water-proof wonven bag.bundled up with iron wire or strip, in wooden case, one label for one bundel.

Option 2: packed with plastic bag for each bar,water-proof woven bag for one bundle, one label for one bundle.