Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

Inconel 625 is a corrosion and oxidation resistant nickel alloy that is used both for its high strength and outstanding aqueous corrosion resistance. Its outstanding strength and toughness is due to the addition of niobium which acts with the molybdenum to stiffen the alloy’s matrix. Alloy 625 has excellent fatigue strength and stress-corrosion cracking resistance to chloride ions. This nickel alloy has excellent weldability and is frequently used to weld AL-6XN. This alloy resists a wide range of severely corrosive environments and is especially resistant to pitting and crevice corrosion. Some typical applications Inconel 625 is used in are chemical processing, aerospace and marine engineering, pollution-control equipment, and nuclear reactors.

Product Characteristic

1)High creep-rupture strength

2)Oxidation resistant to 1800° F

3)Seawater pitting and crevice corrosion resistant

4)Immune to chloride ion stress corrosion cracking

5)Non-magnetic

Product Details:

|

Product Name: |

alloy 625 pipe |

|

|

Material: |

Inconel 625 UNS NO6625 ; DIN W.Nr.2.4856 |

|

|

Product |

Inconel Alloy 625 (UNS designation N06625) is a nickel-based superalloy that possesses high strength properties and resistance to elevated temperatures. It also demonstrates remarkable protection against corrosion and oxidation. Its ability to withstand high stress and a wide range of temperatures, both in and out of water, as well as being able to resist corrosion while being exposed to highly acidic environments makes it a fitting choice for nuclear and marine applications |

|

|

Standard: |

GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

|

|

Inspection: |

ISO,SGS,BV and so on. |

|

|

Application: |

1.Ocean: marine structures in the sea environment, seawater desalination, marine aquaculture, 2.seawater heat exchange, etc. |

|

|

Packaging: |

1. cases packed in wooden cases |

|

|

Delivery: |

7-25days or according to the product |

|

|

Payment: |

L/C,D/A,D/P,T/T,Western Union,MoneyGram,According to customer requirements payments for offline orders. |

|

Chemical Composition, %

|

Cr |

Ni |

Mo |

Co + Nb |

Ta |

Al |

Ti |

C |

Fe |

Mn |

Si |

P |

S |

|

20.00-30.00 |

Remainder |

8.0-10.0 |

1.0 max |

3.15-4.15 |

.40 max |

.40 max |

.10 max |

5.0 max |

.50 max |

.50 max |

.015 max |

.015 max |

Physical Properties:

|

Density |

8.4g/cm³ |

|

Melting Point |

1290℃-1350℃ |

Execution standard:

|

Product |

ASTM |

|

Bar & Profile |

ASTM B446 |

|

Thick Plate, Sheet & Strip |

ASTM B443 |

|

Seamless pipe |

ASTM B444 |

|

Welded nominal pipe |

ASTM B704 |

|

Seamless & Welded pipe fittings |

ASTM B704 |

|

Forgings |

ASTM B564 |

The minimum value of mechanical properties of alloys at the normal temperature:

|

Alloy States |

Tensile Strength |

Yield Strength |

Elongation |

Hardness |

|

RM N/mm² |

RP0.2N/mm² |

A5 % |

HB |

|

|

Sheet & Strip |

≥827 |

≥414 |

≥30 |

≤220 |

|

Plate |

≥827 |

≥414 |

≥30 |

≤220 |

|

Bar |

≥827 |

≥414 |

≥30 |

≤220 |

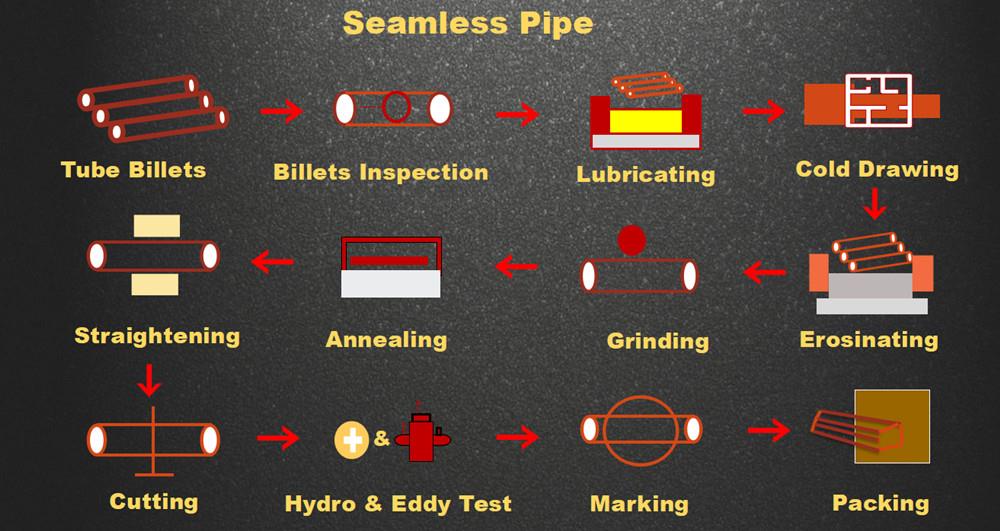

Production Process

Hunan Allianz Metal Products Co., Ltd, established in 1996, which enjoys good fame in the domestic modern integrated stainless steel enterprises. We have provided high-quality products and professional service to 26 provinces of more than 10000 of customers in China and more than 60 countries in the world, Europe, North&South-America, Southeast Asia, Africa, Oceania.

We took part in PH2 project in Hungary, Wartsila shipbuilding project in Spain and the Nitric acid line installation project in Lithuania.

After 21 years of development, our business grows from traditional industries to other new tech fields like oil and petrochemical, new energy, biological medicine, electronic communications, mechanical engineering, special shipping, rail transportation, aviation, and aerospace.

Application area:

1)Aircraft ducting systems

2)Aerospace

3)Jet engine exhaust systems

4)Engine thrust-reverser systems

5)Specialized seawater equipment

6)Chemical process equipment

Production Facility

Packaging And Shipping:

Optin 1: packed with water-proof woven bag.bundled up with iron wire or strip, in wooden case, one label for one bundle.

Option 2: packed with plastic bag for each bar,water-proof woven bag for one bundle, one label for one bundle.