Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

Forged round bars usually have a denser structure than rolled round steel (the result can be known by detecting the looseness of the material by the hot acid etching method). Through heat treatment, it is mainly a higher fatigue strength! Therefore, shaft parts with high requirements should be upset and drawn repeatedly to obtain better fatigue resistance.

Under normal circumstances, the quality of forged round bars (here refers to free forging) under the same deformation ratio is better than that produced by the rolling method, because forging to achieve the same amount of rolling deformation requires repeated forging to be drawn. Long (forging is free deformation and rolling is constrained deformation), so the same billet produces the same finished round bar. Forging is equivalent to an increase in the deformation ratio of rolling by more than 50%. In addition, generally speaking, forging is the entirety of the steel from the surface to the interior Deformation and the rolling surface deform first, so the internal structure, degree of segregation, metal streamlines, etc. of the round bars produced by the two are completely different. The quality of forged round bars is generally better than that of rolled round bars.

| Product Name | Forged Steel Round Bars | |

| Material | Carbon Steel & Alloy Steel | A105,S355,F11, F22, 16Mn, 42CrMo4, 34CrNiMo6, 18CrNiMo7-6, 31CrMoV9, 40CrNiMo,4130,4140, A350 LF2 |

| Stainless Steel |

304L, 316L, F53, F51, 310, 410, F91, F92, 1Cr11Ni2W2MoV, 17-4PH,15-5PH, 1Cr13, 2Cr13, 1Cr18Ni9Ti, GX8-N, A565 XM-32(M152),2Cr11Mo1NiWNb(ST12),X14CrMoVNbN10-2(ST10), X6CrNiTi18-10(320) ,X8CrNiMoVNb16-13, FV535 |

|

| Heat Resistant Steel |

10Cr11Co3W3NiMoVNbNB, X12CrMoWVNbN 2Cr11Mo1NiWVNbN , 13Cr9Mo2Co1NiVNbNB |

|

| High-strength Alloy | 30CrMnSi, 30CrMnSiNi2A , 30Si2MnCrMoVE | |

| Super Alloy |

Inconel 617, Inconel 625, Incoloy 825, Inconel 718, Inconel 718+, Incoloy 907, Incoloy 909, Waspaloy HAYNES188, HAYNES 230, R41, A286, Hastelloy-X, N80A GH3030, GH3128, GH4648, GH4133B, GH3039, GH4099, GH4698, GH4586 |

|

| Ti-Alloy |

TA1, TA7(Ti-5Al-2.5Sn,IM317), TA15(Ti6.5Al1Mo1V2Zr) , TC2(Ti4Al1.5Mn), Ti64, TC11(Ti6.5Al3.5Mo1.5Zr0.3Si) |

|

| Al-Alloy | 2014, 2219, 2A12, 2A50, 2618, 5A06, 5083, 7055, 7085, 7075, LC4, 6061 | |

| Shape | Ring, Shaft, disc, round plate, Dysplasia forgings etc. | |

| Specifications | Customized | |

| MOQ | Customized, 1 piece acceptable | |

| Packing | wooden box, wooden crame/pallet | |

| Delivery time | 7-35 days or Negotiation | |

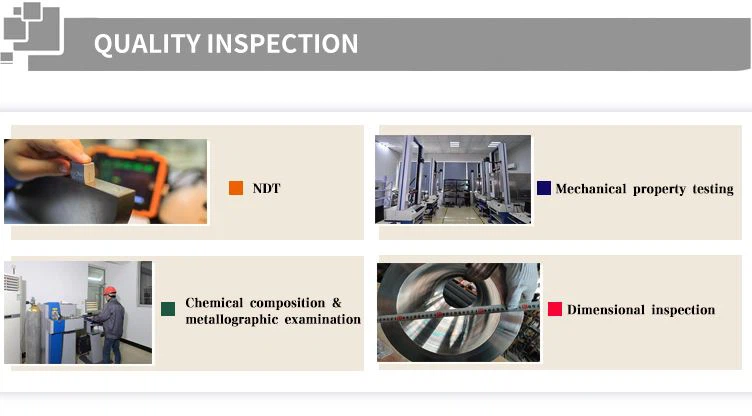

| QC | TUV,SGS,BV,ABS,LR and so on | |

| Application | Chemical, Pharmaceutical & Bio-Medical, Petrochemical & Refinery, Environmental, Food Processing, Aviation, Chemical Fertilizer, Sewage Disposal, Desalination, Waste Incineration etc. | |

| Trade Term | FOB CIF CFR CIP DAP DDP EXW | |

| Payment | T/T, L/C,D/A,D/P, Western Union,MoneyGram,According to customer requirements payments for offline orders. | |

| Transportation | By air, by sea, by train, by truck | |

| Sample | Free | |

| Warranty | Trade assurance after sales service | |