Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

| Product Name | ASTM A53 Gr B ERW Pipe |

| A53B Steel Pipe Diameter | 1inch ~ 26 inch |

| Diameter Tolerance | 603.9mm~616.1mm (acc. to ASTM A53, +/-1% of outside diameter) |

| Wall Thickness | STD,SCH 30, SCH40 etc. |

| Wall Thickness Tolerance | acc. to ASTM A53, +/- 12.5%t |

| Pipe Standard | ASTM A53, API 5L, CSA Z245, A106, ASTM A252, AS 1163, IPS 190 etc |

| A53 Gr B ERW Pipe Grade | Grade A, Grade B or other steel grade required |

| Hydro test pressure | As per ASTM A53 Spec |

| A53 Gr B ERW Pipe Length | SRL, DRL, Random length from 3m to 18m |

| End Finish | Bevelled ends with caps or steel protector |

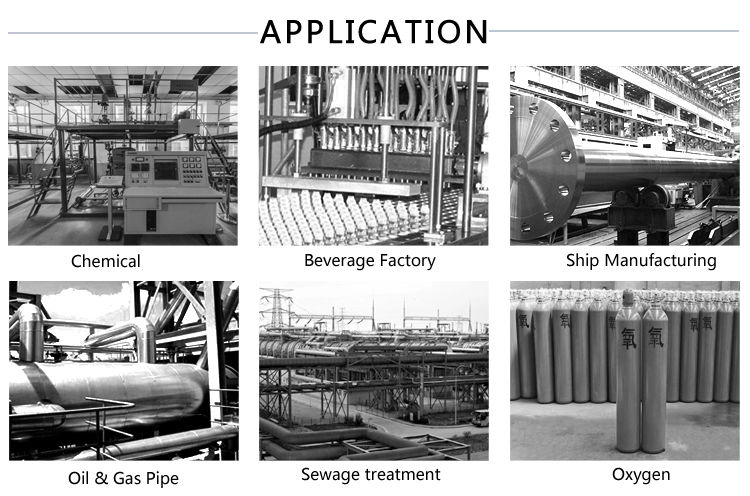

| Application | Fluid pipe, line pipe, water pipe, structure steel tube, piling pipe, construction pipe, bridge pipe etc. |

| Pipe Coating | Black painting, varnish, anti rust oil, FBE, 3PE, 3 layer PE, 3PP etc. |

| Package | Plastic caps on both ends, Steel bundle, or acc. to customers’request |

| Inspection | ISO9001, SGS,BV, GL, Moody or other TPI appointed by customer |

| Capacity | 10000 metric tons per month |

|

|

Type S (seamless) | Type E (electric-resistance welded) | Type F (furnace- welded pipe) | ||

|---|---|---|---|---|---|

|

|

Grade A | Grade B | Grade A | Grade B | Grade A |

| Carbon max. % | 0.25 | 0.30 | 0.25 | 0.30 | 0.3 |

| Manganese % | 0.95 | 1.2 | 0.95 | 1.2 | 1.2 |

| Phosphorous, max. % | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| Sulfur, max. % | 0.045 | 0.045 | 0.045 | 0.045 | 0.045 |

| Copper, max.% | 0.40 | 0.40 | 0.40 | 0.40 | 0.4 |

| Nickel, max. % | 0.40 | 0.40 | 0.40 | 0.40 | 0.4 |

| Chromium, max. % | 0.40 | 0.40 | 0.40 | 0.40 | 0.4 |

| Molybdenum, max. % | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 |

| Vanadium, max. % | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

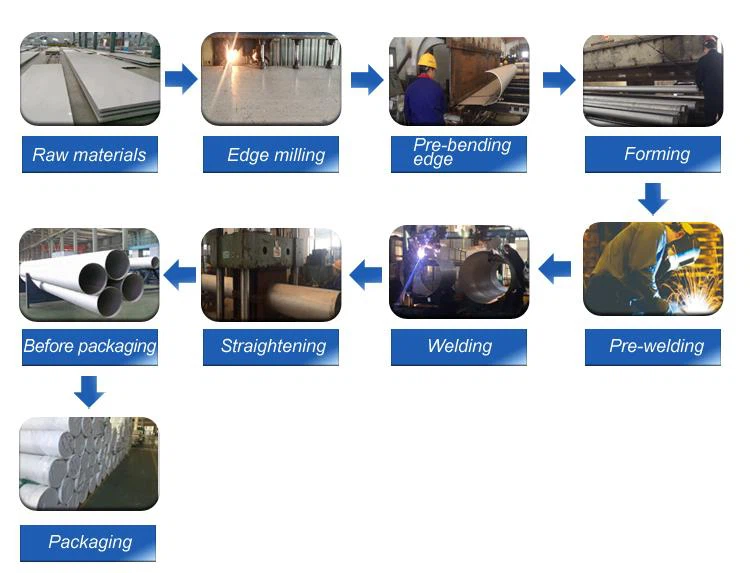

PROCESS OF STAINLESS STEEL PIPE

Have you met tube edge deformation and tube bending problems after getting the goods ?

We give complete and several times of correcting for each tube with particular equipment during production, as well as proper packing to avoid edge deformation or bending before delivery.

Have you got the problems from unacceptable tolerance when you are checking the stainless steel pipes from your previous supplier ?

With our tolerance control machine equipments, strict inspection process has been proceeded to make sure our stainless steel pipes produced and finished by all standards of ASTM, EN, JIS etc.

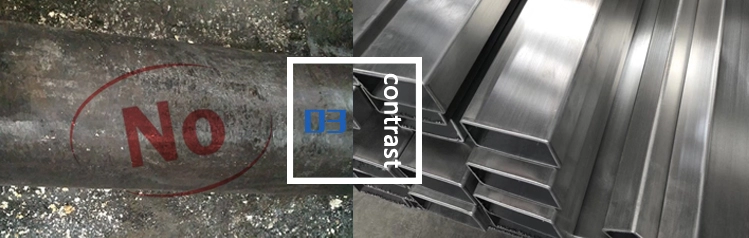

Have you ever met defective and such a bad surface finish ?

There must be complete pickling process given during our stainless steel pipes' production. And we also provide stainless steel pipe surface treatment requirement from our clients, such as polishing, grinding,hairline etc.

Advantages

OUR STAINLESS STEEL PIPE FACTORY TEAM

OWNER STEEL INSITUTE FOR STAINLESS STEEL SEAMLESS & WELDED PIPE

Application