Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

May 24 2023

May 24 2023What we are going to introduce to you today is 316L stainless steel, which has a wide range of applications. It can be used in many aspects of our lives. 316L stainless steel can be used in both the bracelet and case of high-end watches. , And can be used in the fields of chemistry and dyes. In general, 316L stainless steel plays a considerable role in our lives. So do you understand its standard? The following editor will introduce the 316l stainless steel standard in detail.

Introduction to 316l stainless steel

316L stainless steel is often used in heat exchangers of pulp and paper equipment, dyeing equipment, film washing equipment, pipelines, exterior materials for buildings in coastal areas, and bracelets and cases of high-end watches. Equipment used in sea water, chemical, dye, paper, oxalic acid, fertilizer and other production equipment; photography, food industry, coastal facilities, ropes, CD rods, bolts, nuts.

316l stainless steel standard

316L is a grade of stainless steel material, AISI 316L is the corresponding American label, and sus 316L is the corresponding Japanese label. The standard grade in my country is 022Cr17Ni12Mo2 (new standard), and the old grade is 00Cr17Ni14Mo2, which means that it mainly contains Cr and Ni. The number of Mo indicates the approximate percentage.

1. Chemical composition:

Carbon C: ≤0.030

Silicon Si: ≤1.00

Manganese Mn: ≤2.00

sulfur S :≤0.030

Phosphorus P: ≤0.045

Chromium Cr: 16.00~18.00

Nickel Ni: 10.00~14.00

Mo: 2.00~3.00

2. Corrosion resistance:

316L has a wide range of applications in the chemical industry due to its excellent corrosion resistance. 316L is also a derivative steel of 18-8 type austenitic stainless steel, with 2 to 3% Mo element added. The Mo content of 316L makes the steel have excellent pitting resistance and can be safely used in environments containing halogen ions such as Cl-. Because 316L is mainly used for its chemical properties, steel mills have slightly lower requirements for surface inspection of 316L (relative to 304). Customers with higher surface requirements should strengthen the surface inspection.

3. Mechanical properties:

Tensile strength σb (MPa): ≥480

Conditional yield strength σ0.2 (MPa): ≥177

Elongation δ5 (%): ≥40

Reduction of area ψ (%): ≥60

Hardness: ≤187HB; ≤90HRB; ≤200HV

density: 7.98g/cm3;

Specific heat ratio (20℃): 0.502J/(g*K)

Typical use

Most of the requirements for use are to maintain the original appearance of the building for a long time. When determining the type of stainless steel to be selected, the main considerations are the required aesthetic standards, the corrosiveness of the local atmosphere, and the cleaning system to be adopted. However, other applications are increasingly seeking structural integrity or impermeability. For example, roofs and side walls of industrial buildings.

In these applications, the owner’s construction cost may be more important than the aesthetics, and the surface may not be very clean. The effect of using 304 stainless steel in a dry indoor environment is quite good. However, if you want to maintain its appearance outdoors in the countryside and cities, you need to wash it frequently. In heavily polluted industrial areas and coastal areas, the surface will be very dirty and even rusty.

However, to obtain the aesthetic effect in the outdoor environment, nickel-containing stainless steel is required. Therefore, 304 stainless steel is widely used in curtain walls, side walls, roofs and other construction purposes. However, 316 stainless steel is best used in severely corrosive industries or marine atmospheres. Now, people have fully realized the advantages of using stainless steel in structural applications. There are several design criteria that include 304 and 316 stainless steel. Because "duplex" stainless steel 2205 has integrated good atmospheric corrosion resistance with high tensile strength and elastic limit strength, this steel is also included in the European standards.

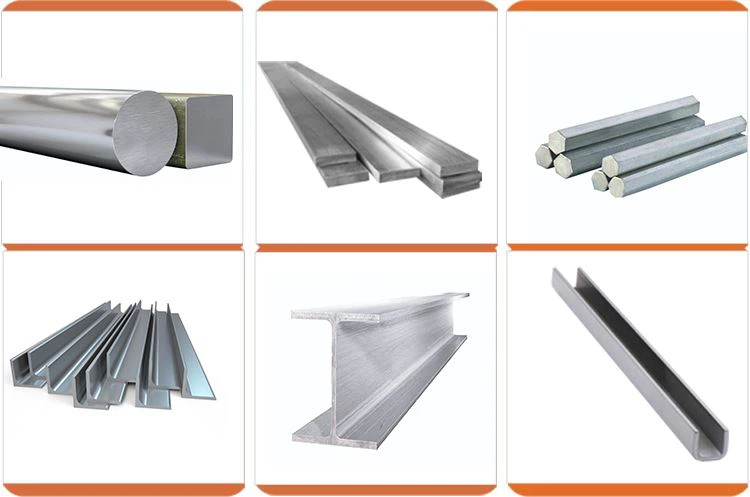

In fact, stainless steel is manufactured in full-standard metal shapes and sizes, and there are many special shapes. The most commonly used products are made of thin plates and strip steel, and medium and heavy plates are also used to produce special products, such as the production of hot-rolled structural steel and extruded structural steel. There are also round, oval, square, rectangular and hexagonal welded pipes or seamless steel pipes and other forms of products, including profiles, bars, wires and castings.

Surface Condition

As will be discussed later, in order to meet the aesthetic requirements of architects, many different commercial surface finishes have been developed. For example, the surface can be highly reflective or matte; it can be smooth, polished or embossed; it can be colored, colored, electroplated, or patterned on the surface of stainless steel, or it can be drawn. To meet the various requirements of designers for appearance. It is easy to maintain the surface condition. Only occasional rinsing can remove dust. Due to its good corrosion resistance, it is also possible to easily remove graffiti contamination or other similar surface contamination on the surface.

Future outlook

Since stainless steel has many ideal properties required by building materials, it can be said to be unique among metals, and its development continues. In order to make stainless steel perform better in traditional applications, the existing types have been improved, and in order to meet the strict requirements of advanced construction applications, new stainless steels are being developed. Due to continuous improvement in production efficiency and continuous improvement in quality, stainless steel has become one of the most cost-effective materials chosen by architects. Stainless steel combines performance, appearance and use characteristics, so stainless steel will still be one of the best building materials in the world.

The above is the introduction of the 316l stainless steel standard. I believe you will have a better understanding of it after reading this article. The scope of its use is relatively wide, mainly because it has many good features. Its appearance is relatively beautiful, and its corrosion resistance is relatively good, although the price is relatively high, but the performance is indeed excellent. It can increase the service life. This is also its advantage. You can experience it after using it.