Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

May 24 2023

May 24 2023

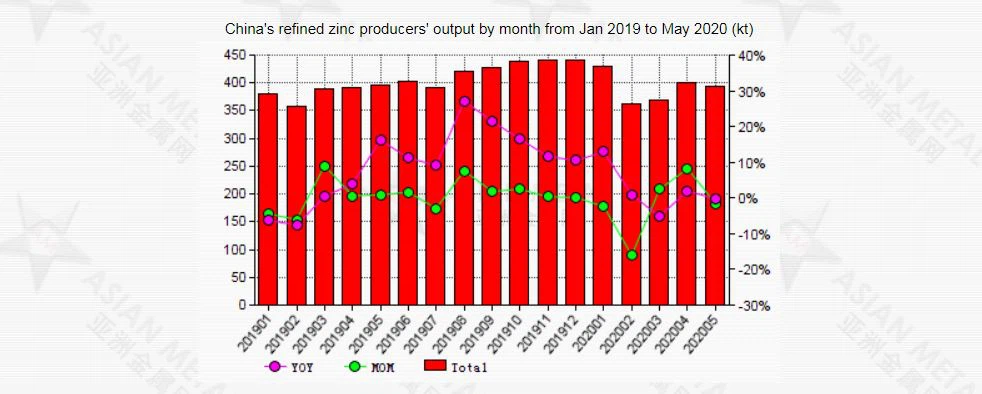

According to Asian Metal Database, China's refined zinc producers produced about 394,400t of the material in May 2020,Down by 1.5% Mon and by 0.4% YoY.

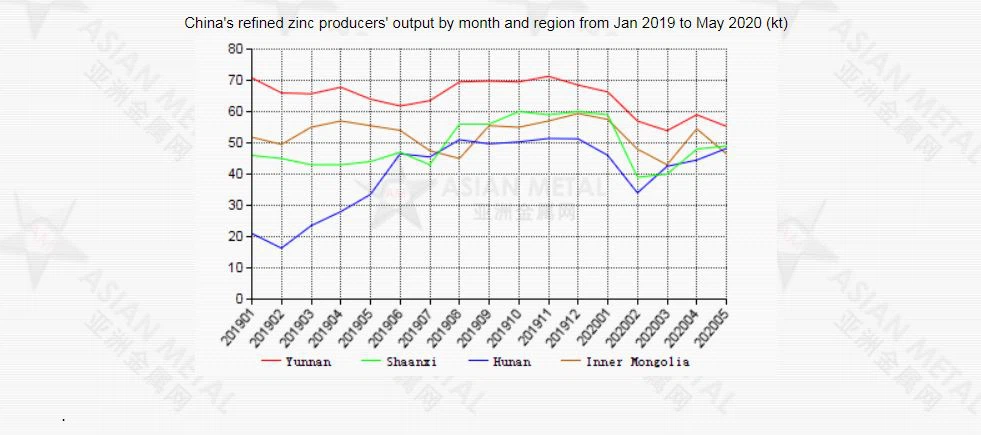

In may, refined zinc producers saw an output of 55300t of the material in Yunnan, dOWN BY 6.3% MOM; In Inner Mongolia, The output recorded 46500t, down by 14.7% from last month. The figure in Shananxi posted 49000t, up by 2.1% MOM. That in Hunan Recorded 48200t, up by 8.3% MOM.

Hunan Anllianz Metal Products Co., Ltd. was established in May 2009. After over ten years of development, it has 20 tons of complete electric arc furnace, AOD refining, LF refining, VD vacuum, 1.5 tons, 3 tons of VIM semi-continuous vacuum furnace smelting equipment, with 1.5 tons, 5 tons of electroslag re-dissolution and gas protection Slag equipment, 5 tons, 1600 tons hydraulic press, 7.5 m, 9 m van-type annealing furnace and lathe, milling machine, CNC machine tools, cylindrical grinder, surface grinder, wire cutting and other production and processing equipment; direct reading spectrometer, hardness tensile, impact Testing equipment, ultrasonic non-destructive flaw detector, metallographic microscope and other perfect testing equipment, the company specializes in special stainless steel, nickel-based alloy, precision alloy, corrosion-resistant alloy shaft parts, square steel, modules, round bars, round cakes, ring parts Production and research and development of forgings such as sleeves. Its products are widely used in water pump valves, automotive ships, mechanical molds, aerospace military, offshore equipment, petroleum and petrochemical, light rail high-speed rail, gas turbines, turbines and other fields.The company's nickel alloy and alloy stainless steel forgings can meet the requirements of different inclusions, residual ferriteaustenite, grain size, impact energy and flaw detection and other high-level requirements. The products are finally applied to GE Energy, Siemens, and Al. Stone, CIMC and other leading companies in the industry, and won the praise of users.Advantages:1.raw materials: refining (vacuum + electroslag). 2.The product has uniform chemical composition, high purity, low gas content and no defects on the surface. 3.quality guaranty: feed inspection, process control (feeding control, self-inspection, inspection, product inspection). 4.the United States GE (660), France Alstom (625), CIMC (1.4418, 17-4PH) and other companies adopted. 5.delivery capacity: stable production, fast delivery. 6.the order quantity is not required, to map custom. 7.Low price: large-scale production reduces costs, 15% lower than the same quality products in Europe and America. 8.We are the NO. 1 of exporting high-temperature alloy forging in Hunan province. 9.Provide one-to-one technical service.Raw materials: new materials (using clean new materials, no turning materials, no oil and returning materials)Smelting method: vacuum smelting + electroslag re-dissolution, vacuum smelting - vacuum self-consumption and re-dissolutionPrice: 15% lower than Japan, Europe and AmericaBenefits: If you use 20 tons of material ($250,000) a month, it means you can save $37,500 a month and save $450,000 a year.Evidence: Why is it so cheap?The raw materials are self-refined, and the advantages of their own processing are subsequently pursued. The forgings such as 718, C276,925, 625 and monel400 are professionally produced , and produce on a large scale.

Contact us:marketing@ronsteel.com