Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

May 24 2023

May 24 2023The vital types of Stainless Steel flanges are the welding neck, long welding neck, slip-on, outlet weld, lap joint, threaded and also blind flanges. In enhancement to these standard flanges, some special ones exist, called Weldoflange/Nipoflange as well as Elboflange, swivel flange, expander/reducer flange, and orifice flanges.

Table of Material:

The sort of flange to be utilized for a piping application depends, generally, on the required strength for the flanged joint. Flanges are used, additionally to welded links, to assist in upkeep procedures (a flanged joint can be dismantled swiftly and comfortably).

Let's currently dive in, showing the essential kinds of flanges with pictures.

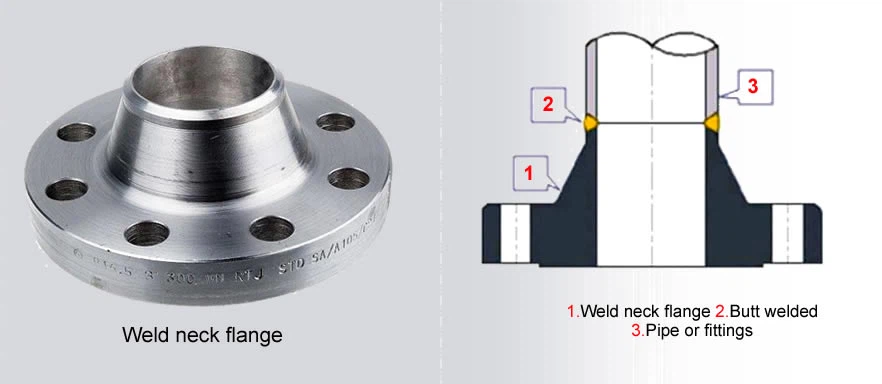

Weld neck flange ASME B16.5 as well as B16.47. Weld Neck Flange welding

A welding neck flange (" WN") features a lengthy tapered center that can be welded with a pipe.

This flange kind is made use of, generally, in high-pressure and also high/low temperatures applications that call for an unrestricted flow of the fluid conveyed by the piping system (the bore of the flange matches with the bore of the pipeline).

The absence of stress drops prevents negative results as turbulence and erosion/corrosion of the steels in the closeness of the flanged joints.

The tapered center permits a smooth distribution of the mechanical stress and anxiety in between the pipe and also the weld neck flange and facilitates the execution of radiographic evaluations to discover possible leaks as well as welding issues.

The dimension of the flange (NPS and also the pipe routine) shall match the dimension of the linking pipe.

A welding neck flange is connected to a pipe by a solitary complete infiltration V-shaped butt weld. The dimension and weights of ASME weld neck flanges are displayed in this post.

Long weld neck flange

Lengthy weld neck flanges (" LWN") are similar to weld neck flanges, with the exception that the neck (conical hub) is prolonged as well as imitates a dull extension.

Long weld neck flanges are usually used on barrels, columns or vessels. These flange kinds are available likewise in the heavy barrel (HB) and also equal barrel (E) types.

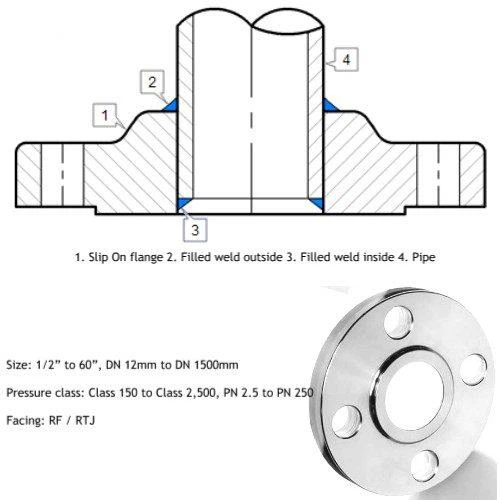

SLIP ON FLANGE

Slip on flange ASME B16.5 Slip On Flange, fillet welds

A slip-on flange is linked to the pipe or the fittings by 2 fillet welds, one performed within and also one outside the dental caries of the flange.

The birthed size of a slip-on flange is larger than the outdoors diameter of the linking pipe, as the pipe has to move inside the flange to be linked by the implementation of a fillet weld.

Slip-on flanges are also defined "Hubbed Flanges" as well as they are simple to acknowledge because of their compact and slim form.

The dimensions as well as weights of slip-on flanges ANSI/ASME are offered on this web page.

Flanged joints made with slip-on flanges are, in the future, a little bit a lot more breakable than connections made with welding neck flanges (in comparable service problems). This seems due to the following realities:

a welding neck flange includes a conical center, lacking in an outlet bonded flange, which distributes the mechanical tension between the pipe and the flange more uniformly

a welding neck joint as just one welding area as opposed to two (socket weld flange).

Another benefit of the welding neck flange is that it can be attached either to installations and also pipes, whereas outlet weld flanges suit pipelines just.

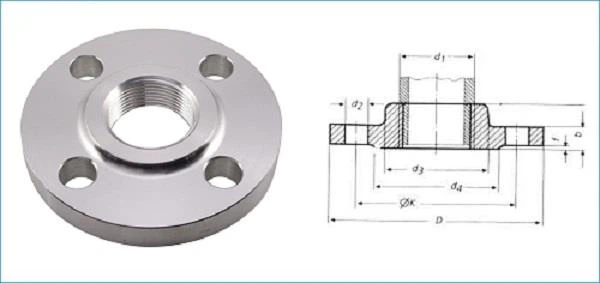

THREADED FLANGE

Threaded flange ASME B16.5 Threaded flange

Threaded flanges are signed up with to pipelines by screwing the pipe (which has a male thread, generally NPT per ASME B1.20.1) onto the flange, without joint welds (in particular cases, though, little welds are related to increase the toughness of the connection).

Threaded flanges are available in measure to 4 inches as well as multiple pressure ratings, nonetheless, they are used, mostly, little dimension piping in reduced stress and low-temperature applications, like water and also air utility services.

Threaded flanges are likewise a compulsory demand in explosive locations, such as filling station and also plants, as the execution of bonded links in such environments would be dangerous.

Consult this short article, to discover concerning the measurement of ANSI/ASME threaded flanges.

OUTLET WELD FLANGE:

Outlet bonded flange ASME B16.5. Outlet Bonded Flange, 1 fillet weld

Outlet weld flanges are connected to pipelines making use of a solitary fillet weld carried out on the external side of the flange (different from the slip-on flange kind that requires two welds).

According to ASME B31.1, to carry out a flanged connection using a socket weld flange, the pipe will be at initial put in the outlet of the flange till it gets to the bottom of the flange, then it ought to be raised by 1.6 mm as well as finally welded.

This space shall be delegated permit appropriate positioning of the pipeline inside the flange socket after the solidification of the weld.

Socket Bonded Flanges are used for high-pressure as well as small-size piping that do not move extremely harsh fluids.

This as a result of the reality that these flange kinds are subject to corrosion in the space area between completion of the pipeline and the shoulder of the socket.

Their fixed stamina of outlet weld flanges is similar to slip-on flanges', but their exhaustion strength is greater due to the existence of a solitary, instead of dual, fillet weld.

Dimensions and weights of socket-weld flanges (ASME/ANSI) are reported right here.

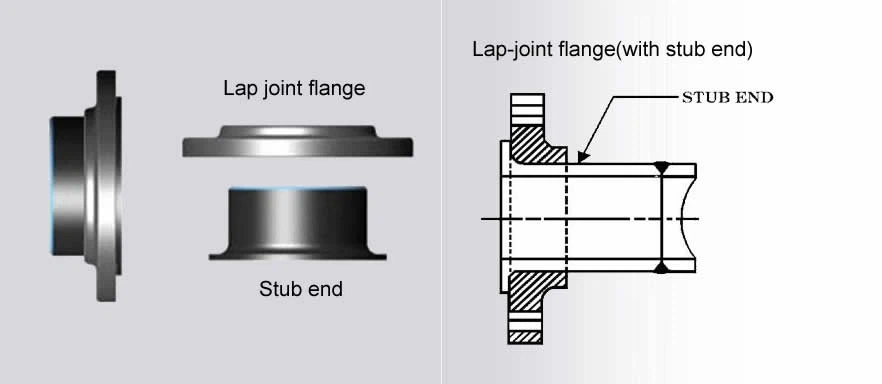

LAP JOINT FLANGE:

Lap joint flange ASME B16.5 flanged joint with stub end

Lap joint flanges feature a level face as well as are always made use of in conjunction with a stub end.

Lap joint flanges look like, in shape, slip-on flanges with the exception of the distance at the going across of the flange face as well as the bore to suit the flanged section of the stub end.

A lap joint flange slides over the pipe as well as seats on the back of the stub end and the two are united by the stress of the bolts.

The use of lap joint flanges in combination with stub ends is an affordable solution for stainless steel or nickel alloy pipes, as the product of the lap joint flange can be of a lower quality (normally carbon steel) than the product of the stub end (which has to match the pipe grade, as in contact with the conveyed fluid).

This arrangement, as a result, has these two advantages:

minimizes the general cost of the pipeline's flanged joints, as the use of greater quality products is decreased;

bolting operations are streamlined, as the lap joint flange can be turned around the pipe to help with bolts placement.

The dimensions and weights of lap joint flanges are displayed in this short article.

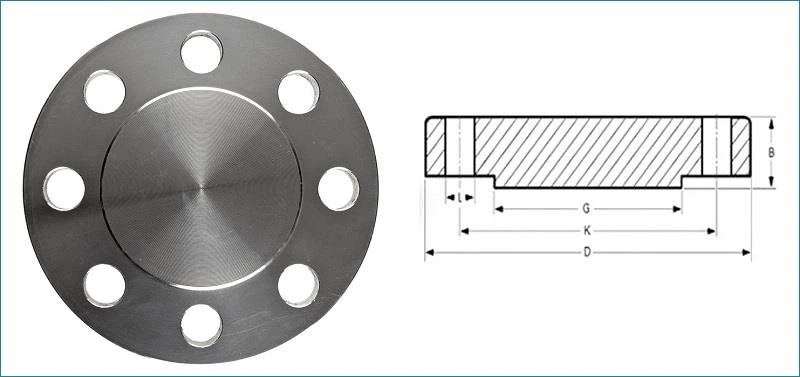

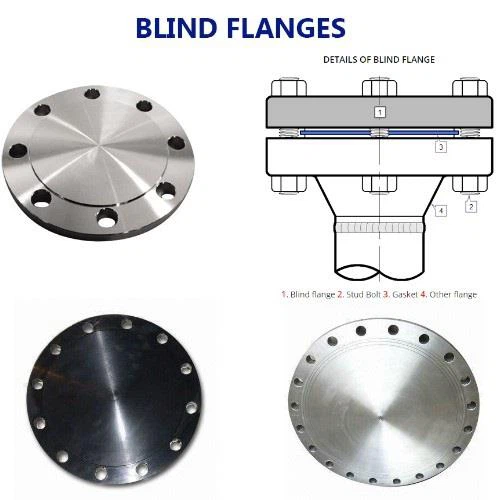

BLIND FLANGE:

As opposed to all the flange kinds seen over, blind flanges do not have a center hole, and are made use of to blind or secure a pipeline, a valve/pressure vessel and also block the flow of the fluid.

Blind flanges have to stand up to impressive mechanical anxiety because of the system pressure and also the needed bolting pressures.

Blind flanges allow very easy accessibility to the pipe, as they can be quickly unbolted to allow the operator carry out tasks inside the terminal end of the pipeline (this is also the reason that the blind flange kind is made use of as manhole for stress vessels, sometimes).

It is possibly intriguing to observe that, while this flanges type is much easier to manufacture, they are sold at an exceptional average price per kg compared to the various other flange types.

Describe this write-up to learn more about the measurements of blind flanges per ANSI/ASME B16.5.

SPECIAL KINDS OF FLANGES:

A Nipoflange is made use of for branch pipes at 90 degrees and is an item made by integrating a welding neck flange with a built Nipolet.

Nevertheless, a Nipoflange is a strong solitary piece of forged steel as well as not 2 various products welded with each other.

To install a Nipoflange, the piping personnel has to bond the Nipolet part of the gadget on the run pipe as well as screw the flanged part on the flange of the branched pipe.

Nipoflanges are available in different materials, such as carbon steel ASTM A105 (high-temperature service), ASTM A350 (low-temperature carbon steel), ASTM A182 (stainless steel qualities, including duplex as well as super duplex) as well as nickel alloys (Inconel, Incoloy, Hastelloy, etc).

Nipoflanges are also manufactured in the strengthened variant, which has additional mechanical toughness compared to a standard Nipoflange.

WELDO FLANGE:

A Weldoflange is conceptually comparable to a Nipoflange, as that they are a combination of a weld neck flange and also a branch fitting connection (a Weldolet in this case). Weldoflanges are constructed out of a solitary item of strong created steel, not by welding separate components together.

ELBOFLANGE As Well As LATROFLANGE

Various other much less common types of flange Olets is the so-called Elboflange (a mix of a flange and an Elbolet) as well as "Latroflange" (mix of a flange with a Latrolet). Elboflanges are utilized to branch a pipeline at 45 degrees.

Elbo flange:

SWIVEL FLANGE

Swivel ring flanges promote the placement of the bolt holes between both breeding flanges, an attribute that is practical in many circumstances, such as the installation of large size pipes, subsea and overseas pipelines, pipe operates in shallow waters and also similar environments.Swivel flanges fit oil, gas, hydrocarbons, water, chemical and also other requiring fluids in petrochemical and water monitoring applications.

In the case of a big size pipeline, for example, the pipeline is fitted, at one end, with a typical welding neck flange, as well as with a swivel flange at the other end: by just revolving the swivel flange on the pipe, the operators can accomplish a perfect placement of the bolt holes in such a way easier and also faster method.

The significant standards for swivel ring flanges are ASME/ANSI, RACKET, BS, EN, ISO, etc. The most usual requirement for petrochemical application is the ANSI/ASME B16.5 or ASME B16.47.

Swivel flanges are available in all the common shapes of typical flanges, i.e. weld-neck, slip-on, lap-joint, outlet weld etc, in all worldly qualities and also in a vast dimensional range (dimensions can vary from 3/8" to 60" as well as pressure score from 150 to 2500).

Swivel flanges can be produced in carbon steel (ASTM A105), alloy steel (ASTM A182 F1, A182 F5, A182 F9, A182 F91), as well as, stainless-steel (ASTM A182 F304, A182 F304L, A182 F316, A182 F316L).

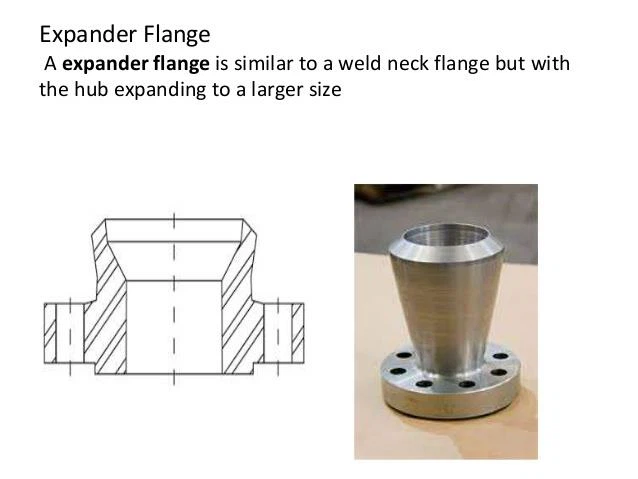

INCREASING FLANGE (" EXPANDER").

Increasing and reducing flanges: Expander flange.

Expander flange.

Broadening flanges, or "expander flanges", are used to boost the birthed of the pipeline from a certain point to an additional or to link pipes to other mechanical devices such as pumps, compressors, and valves that have various inlets dimensions.

The broadening flange stood for aware is a welding neck flange with a bigger bore on the non-flanged end.

Increasing flanges can be made use of to enhance the run pipe birthed just by one or optimal two dimensions and also not extra (example: from 2 to 3 or optimum 4 inches).

Expander flanges are a more affordable (and lighter) remedy contrasted to the combination of a buttweld reducer as well as a standard flange (which is the standard solution for pipe birthed boosts above 2 dimensions).

One of the most usual products for expanding flanges are A105 (high-temp. carbon steel), A350 (LTCS) as well as ASTM A182 (stainless steel as well as above).

Stress scores as well as measurements of increasing flanges are in conformity with the ANSI/ASME B16.5 specification and are readily available with elevated or level face (RF, FF).

increasing flange dwg.

The drawing of an ASME broadening flange.

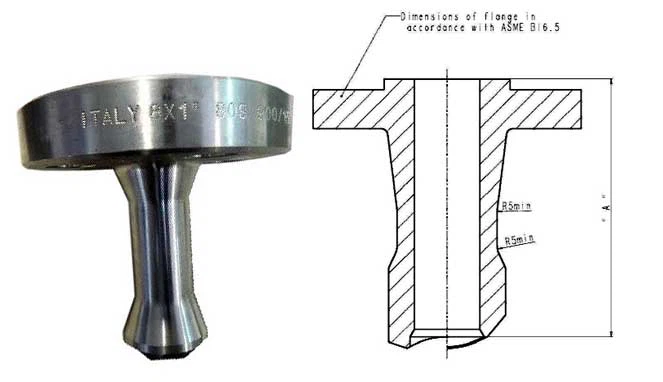

MINIMIZING FLANGE (" REDUCER").

Reducer flange:

Lowering flanges, otherwise called reducer flanges, have an opposite feature than expander flanges seen over, i.e. they are utilized to lower the birthed of a pipeline.

The birthed of the run pipe can be safely minimized by just 1 or 2 dimensions (or else a solution based on the combination of a butt weld reducer and also a conventional flange needs to be utilized).

Reducing flanges are available in many sizes and worldly qualities, as well as are not normally readily available from supply.

Decreasing flanges follow the same factors to consider in regards to requirements, dimensions and material qualities as expander flanges.

The last sort of forged item that looks like the shape of a flange is the supposed phenomenon blind: while not appropriately a flange, a blind (or a ring spacer or spade) is utilized in between pipes to isolate the pipeline mechanically and in a very simple way. Even more information are given in another area of our Wiki for piping.