Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

Inconel Alloy 625 ( UNS N06625 ) is a nickel-based super alloy with high strength and resistance to high temperature. Products and technology applications of Inconel 625 include seawater components, torch reactor aircraft piping system, Inconel 625 manufacturing, and special seawater equipment, etc.

Product Characteristic

1)High-temperature resistance

1)High pressure

1)High erosion

1)High abrasion

Product Details:

|

Product Name: |

Hot selling Nickel Alloy Inconel 625 Round Tube / Inconel 625 Seamless Pipe |

|

|

Material: |

Inconel 625 UNS NO6625 ; DIN W.Nr.2.4856 |

|

|

Product |

Inconel Alloy 625 (UNS designation N06625) is a nickel-based superalloy that possesses high strength properties and resistance to elevated temperatures. It also demonstrates remarkable protection against corrosion and oxidation. Its ability to withstand high stress and a wide range of temperatures, both in and out of water, as well as being able to resist corrosion while being exposed to highly acidic environments makes it a fitting choice for nuclear and marine applications |

|

|

Standard: |

GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

|

|

Inspection: |

ISO,SGS,BV and so on. |

|

|

Application: |

1.Ocean: marine structures in the sea environment, seawater desalination, marine aquaculture, 2.seawater heat exchange, etc. |

|

|

Packaging: |

1. cases packed in wooden cases |

|

|

Delivery: |

7-25days or according to the product |

|

|

Payment: |

L/C,D/A,D/P,T/T,Western Union,MoneyGram,According to customer requirements payments for offline orders. |

|

Chemical Composition:

C ≤0.1 /Cr 20.0-23.0 / Ni ≥58 / Mo 8.0-10.0 / Si 0.5 / Mn ≤0.5 / P≤0.015 / S ≤0.015 / Al ≤0.4 / Ti ≤0.4 / Co ≤1.0 / Fe ≤5.0

Physical Properties:

|

Density |

8.4g/cm³ |

|

Melting Point |

1290℃-1350℃ |

Execution standard:

|

Product |

ASTM |

|

Bar & Profile |

ASTM B446 |

|

Thick Plate, Sheet & Strip |

ASTM B443 |

|

Seamless pipe |

ASTM B444 |

|

Welded nominal pipe |

ASTM B704 |

|

Seamless & Welded pipe fittings |

ASTM B704 |

|

Forgings |

ASTM B564 |

The minimum value of mechanical properties of alloys at the normal temperature:

|

Alloy States |

Tensile Strength |

Yield Strength |

Elongation |

Hardness |

|

RM N/mm² |

RP0.2N/mm² |

A5 % |

HB |

|

|

Sheet & Strip |

≥827 |

≥414 |

≥30 |

≤220 |

|

Plate |

≥827 |

≥414 |

≥30 |

≤220 |

|

Bar |

≥827 |

≥414 |

≥30 |

≤220 |

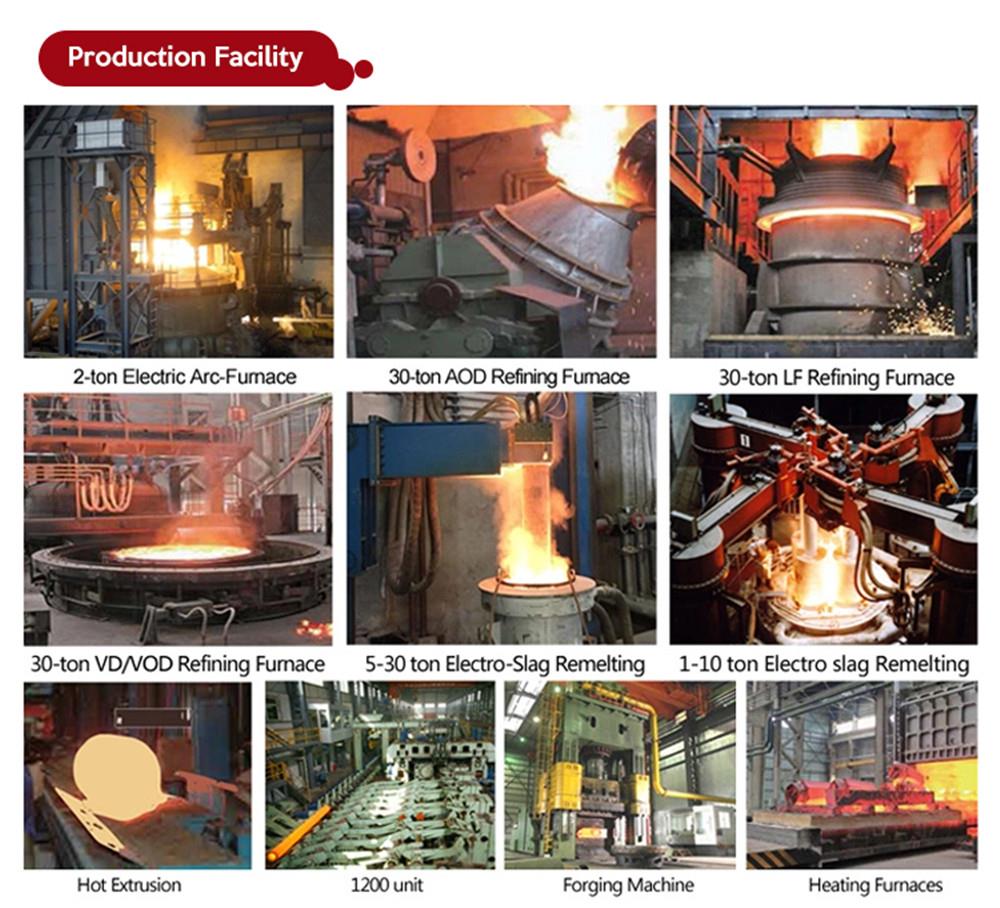

Production Process

Our high-temperature alloy production base is in Jiangsu (Suzhou) province, and our factory has 168 employees and 12 technicians. The main products are bars, tubes, and forgings, and the main material is 254SMO / 253MA/ XM-19 / Inconel 625 / Inconel 718 / Hastelloy C276 / Incoloy A-286 / Monel 400 / Monel K-500.

Our raw materials are mainly from Jinchuan, whose nickel output ranks third in the world. We are the strategic partner of Jinchuan group nickel alloy co., LTD.

At present, the company has 1.5 tons of VIM vacuum induction furnace, 1-5 tons of electro-slag remelting furnace and hydrogen atmosphere protection electro-slag ingot furnace, a full set of 20 tons of electric furnace, AOD refining furnace, LF ladle refining furnace, VD vacuum furnace, 5 tons of forging hammer and 8 mn fast forging machine, etc..

Available Shape of High-temperature alloy steel

Application area:

Products and technology applications of Inconel 625 include seawater components, torch reactor aircraft piping system, Inconel 625 manufacturing, special seawater equipment, chemical process equipment, turbine cover ring, Engine thrust reversal systems and jet engines exhaust systems.

Production Facility

Testing Equipment

Optin 1: packed with water-proof wonven bag.bundled up with iron wire or strip, in wooden case, one label for one bundel.

Option 2: packed with a plastic bag for each bar,water-proof woven bag for one bundle, one label for one bundle.

FAQ:

Q: Are you a factory or trading company?

A: We're a factory with over 20 years of experience in stainless steel & alloy steel industry.

Q: How can you ensure your price and quality?

A: We process a hundred advanced machines which save much cost from the source of production, ensure our customers' competitive price. Over 20 years of experience ensure our high quality in this industry.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in ZhangWan Science and Technology Park, Jiangsu, China, which is renowned as the hometown of ss alloy steel. If you want to visit our factory, we warmly welcome you here.

Q: Do you provide samples of alloy 625? Is it free or extra?

A: No, we need some cost and the cost of freight.

Q: What is your terms of payment?

A: Payment less than 1000USD, 100% in advance. Payment over 1000USD, 30%T/T in advance, balance before shipment.