Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

Monel 400 is a nickel-copper alloy (about 67% Ni – 23% Cu) that is resistant to seawater and steam at high temperatures as well as to salt and caustic solutions. Alloy 400 is a solid solution alloy that can only be hardened by cold working. This nickel alloy exhibits characteristics like good corrosion resistance, good weldability and high strength. A low corrosion rate in rapidly flowing brackish or seawater combined with excellent resistance to stress-corrosion cracking in most freshwaters, and its resistance to a variety of corrosive conditions led to its wide use in marine applications and other non-oxidizing chloride solutions. This nickel alloy is particularly resistant to hydrochloric and hydrofluoric acids when they are de-aerated. As would be expected from its high copper content, alloy 400 is rapidly attacked by nitric acid and ammonia systems.

Monel 400 has great mechanical properties at subzero temperatures, can be used in temperatures up to 1000° F, and its melting point is 2370-2460° F. However, alloy 400 is low in strength in the annealed condition so, a variety of tempers may be used to increase the strength.

Product Characteristic:

1.Resistant to seawater and steam at high temperatures

2.Excellent resistance to rapidly flowing brackish water or seawater

3.Excellent resistance to stress corrosion cracking in most freshwaters

4.Particularly resistant to hydrochloric and hydrofluoric acids when they are de-aerated

5.Offers some resistance to hydrochloric and sulfuric acids at modest temperatures and concentrations, but is seldom the material of choice for these acids

6.Excellent resistance to neutral and alkaline salt

7.Resistance to chloride-induced stress corrosion cracking

8.Good mechanical properties from sub-zero temperatures up to 1020° F

9.High resistance to alkalis

Product Details:

|

Product Name: |

monel 400 seamless pipe |

|

|

Standard: |

GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

|

|

Inspection: |

ISO,SGS,BV and so on. |

|

|

Application: |

Air Condition or Refrigerator, Water Tube, Water Heater, Oil Cooler Pipe, Heat Exchanger,Refrigeration |

|

|

Packaging: |

1. cases packed in wooden cases |

|

|

Delivery: |

7-25 days or according to the product |

|

|

Payment: |

L/C,D/A,D/P,T/T,Western Union,MoneyGram,According to customer requirements payments for offline orders. |

|

Chemical Composition, %

|

C |

Mn |

S |

Si |

Ni |

Cu |

Fe |

|

.30 max |

2.00 max |

.024 max |

.50 max |

63.0 min |

28.0-34.0 |

2.50 max |

| ASTM Specification | |

|

Pipe Smls |

B165 |

| Pipe Welded |

B725 |

| Tube Smls | B163 |

| Tube Welded |

|

Corrosion Resistant of Monel 400

Alloy 400 is virtually immune to chloride-ion stress corrosion cracking in typical environments. Generally, its corrosion resistance is very good in reducing environments, but poor in oxidizing conditions. It is not useful in oxidizing acids, such as nitric acid and nitrous. Nevertheless, it is resistant to most alkalis, salts, waters, food products, organic substances and atmospheric conditions at normal and elevated temperatures.

This nickel alloy is attacked in sulfur-bearing gases above approximately 700° F and molten sulfur attacks the alloy at temperatures over approximately 500° F.

Monel 400 offers about the same corrosion resistance as nickel but with higher maximum working pressures and temperatures and at a lower cost due to its superior ability to be machined.

Application area:

Marine engineering

Chemical and hydrocarbon processing equipment

Gasoline and freshwater tanks

Crude petroleum stills

De-aerating heaters

Boiler feedwater heaters and other heat exchangers

Valves, pumps, shafts, fittings, and fasteners

Industrial heat exchangers

Chlorinated solvents

Crude oil distillation towers

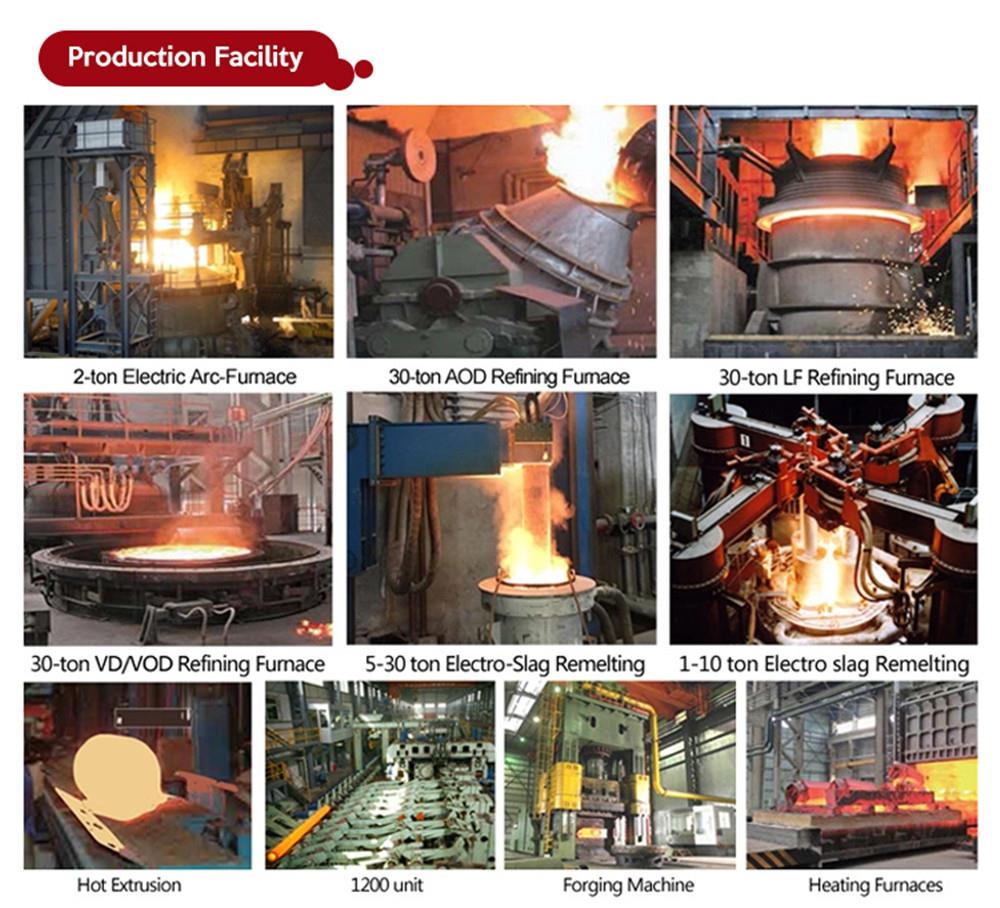

Production Facility

Hunan Allianz metal products Co., Ltd. was founded in 1996, foreign trade began in 2013. Our company has three production bases (Shanghai, Jiangsu, and Hunan), with an annual sales volume of 30 million US Dollars. Our sales volume of high-temperature alloy is 10 million US Dollars, with an annual output of 600 tons.

Our products have been exported to more than 50 countries and regions, the main markets are Southeast Asia, East Asia, North America, South America, Australia, Russia.

Our high-temperature alloy production base is in Jiangsu (Suzhou) province, and our factory has 168 employees and 12 technicians. The main products are bars, tubes and forgings, and the main material is 254SMO / 253MA/ XM-19 / Inconel 625 / Inconel 718 / Hastelloy C276 / Incoloy A-286 / Monel 400 / Monel K-500.

Our raw materials are mainly from Jinchuan, whose nickel output ranks the third in the world. We are the strategic partner of Jinchuan group nickel alloy co., LTD.

At present, the company has 1.5 tons of VIM vacuum induction furnace, 1-5 tons of electro-slag remelting furnace and hydrogen atmosphere protection electro-slag ingot furnace, a full set of 20 tons of electric furnace, AOD refining furnace, LF ladle refining furnace, VD vacuum furnace, 5 tons of forging hammer and 8 mn fast forging machine, etc..

Bars and forgings:

our smelting method is VIM+ESR,if you have higher requirements,we have better smelting methods like VIM+VAR (vacuum smelting + vacuum consumable arc smelting - double vacuum), and Penetration testing and ultrasonic detection will be carried out.

Tubes: Our nickel alloy tubes are hot-extruded.

Optin 1: packed with water-proof woven bag.bundled up with iron wire or strip, in wooden case, one label for one bundle.

Option 2: packed with plastic bag for each bar,water-proof woven bag for one bundle, one label for one bundle.