Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

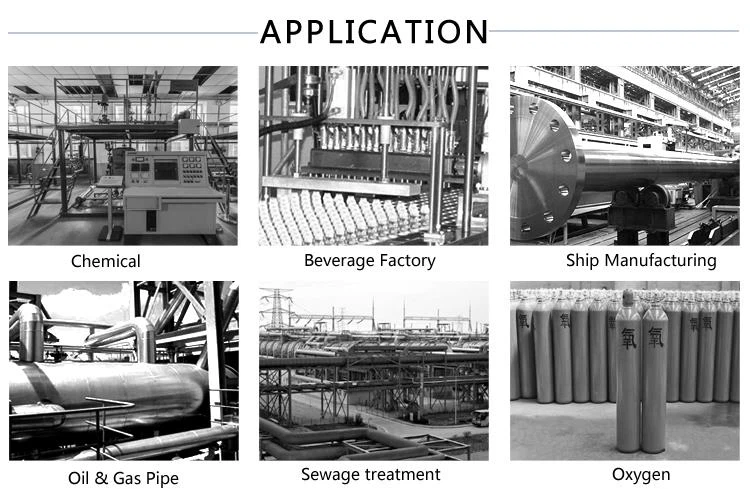

Ronsco has over 20 years of experience in manufacturing Nickel Alloy pipes & tubes, pipe fittings, there are Nickel Alloy seamless pipes and welded pipes. The main grades of our Nickel alloy pipes are Inconel 601, 625, Inconel 718, Monel 400, Monel K500, and 254SMO, DUPLEX 2507, 17-4PH special grades.

Inconel 625 seamless pipe Manufacturer and supplier

|

Product Details |

|

|

Product name |

Inconel 625 seamless pipe Manufacturer and supplier |

|

Brand name |

RONCO |

|

Standard |

ASTM B443,B444 B446,B564:AMS 5581,5599,5666,5837,5869,JIS G4901,G4902 G4903, G4904 |

|

Material |

Inconel 625 |

|

Surface |

Pickling, polishing, BA |

|

Certificate |

BV, LR, GL, NK, RMRS |

|

Packing |

In bundles with waterproof material, in wooden cases |

|

Shipment |

By sea, by air, by express |

|

Chemical Composition(%) |

|||||||||||

|

Grade |

C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu | |

|

201 |

0.15 | 0.75 | 5.5~7.5 | 0.060 | 0.03 | 16.00~18.00 | 3.5~5.5 | - | - | 0.08 | 1.5 |

| 202 | 0.15 | 1.00 | 7.5~10.00 | 0.060 | 0.03 | 17.00~19.00 |

4.0~6.0 |

- | 0.25 | ||

| 301 | 0.15 | 1.00 | 2.00 | 0.045 | 0.03 | 16.00~18.00 | 6.00~8.00 | - | |||

| 302 | 0.15 | 1.00 | 2.00 | 0.035 | 0.03 | 17.00~19.00 | 8.00~10.00 | - | |||

| 304 | 0.07 | 1.00 | 2.00 | 0.045 | 0.03 | 18.00~20.00 | 8.00~10.50 | - | |||

| 304L | 0.030 | 1.00 | 2.00 | 0.045 | 0.03 | 18.00~20.00 | 9.00~13.00 | - | |||

| 310S | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 24.00~26.00 | 19.00~22.00 | - | |||

| 316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 | |||

| 316L | 0.03 | 1.00 | 2.00 | 0.045 | 0.03 | 16.00~18.00 | 12.00~15.00 | 2.00~3.00 | |||

| 321 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 17.00~19.00 | 9.00~13.00 | - | |||

|

430 |

0.12 | 0.75 | 1.00 | 0.040 | 0.03 | 16.00~18.00 |

|

- | |||

| 2205 | 0.03 | 1.00 | 2.00 | 0.030 | 0.015 | 22.00~23.00 | 4.5~6.5 | 2.5~3.5 | |||

| 2507 | 0.03 | 0.08 | 1.20 | 0.035 | 0.015 | 24.00~26.00 | 6.00~8.00 | 3.0~5.0 | |||

| 904L | 0.02 | 1.00 | 2.00 | 0.045 | 0.035 | 19.00~23.00 | 23.00~28.00 | 4.0~5.0 |

1.0~2.0 |

||

|

INCONEL 028 |

0.03 | 1.00 | 2.50 | 0.030 | 0.030 | 28.0 | 34.0 | 4.0 | 1.4 | ||

|

MONEL 400 |

0.30 | 0.5 | 2.00 | - | 0.024 | - | 63.0 | - | 34.0 | ||

|

INCONEL 800 |

0.10 | 1.00 | 1.50 | - | 0.015 | 23.0 | 35 | 4.0~5.0 | - | 0.75 |

0.6 0.6 |

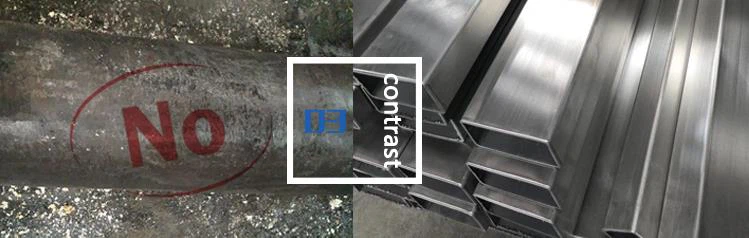

Have you met tube edge deformation and tube bending problems after getting the goods ?

We give complete and several times of correcting for each tube with particular equipment during production, as well as proper packing to avoid edge deformation or bending before delivery.

Have you got the problems from unacceptable tolerance when you are checking the stainless steel pipes from your previous supplier?

With our tolerance control machine equipment, a strict inspection process has been proceeded to make sure our stainless steel pipes produced and finished by all standards of ASTM, EN, JIS, etc.

Have you ever met defective and such a bad surface finish?

There must be a complete pickling process given during our stainless steel pipes' production. And we also provide stainless steel pipe surface treatment requirements from our clients, such as polishing, grinding, hairline, etc.

OUR Nickel Alloy Seamless PIPE FACTORY TEAM

OWNER STEEL INSITUTE FOR Nickel Alloy SEAMLESS & WELDED PIPE

PROCESS OF NICKEL Alloy SEAMLESS PIPE

Ronsco Team