Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

Monel400 is a corrosion-resistant alloy with the largest amount, the widest application and excellent comprehensive properties. This alloy has excellent corrosion resistance in hydrofluoric acid and fluorine gas media, and also has excellent corrosion resistance to hot concentrated lye. At the same time, it is resistant to corrosion from neutral solutions, water, sea water, air, organic compounds, etc. An important feature of this alloy is that it generally does not produce stress corrosion cracks and has good cutting performance.

Product name: Monel400\UNS N04400

International common name: MONEL alloy400,UNS N04400, NiCu30Fe W-Nr: 2.4360,Nicorros-alloy400,ATI400,,NAS NW400

Executive standard: ASTM B127/ASME SB-127, ASTM B163/ASME SB-163, ASTM B165/ASME SB-165

Main components: carbon (C) ≤ 0.30, nickel (Ni) ≥ 63.0, silicon (Si) ≤ 0.5, sulfur (S) ≤ 0.024, iron (Fe) ≤ 2.5, manganese (Al) ≤ 2.0, copper (Cu) 28.0 ~34.0

Physical properties: density: 8.9g/cm3, melting point: 1300-1350 ℃, magnetic: none

Mechanical properties: tensile strength: σb≥480Mpa, yield strength σb≥195Mpa: elongation: δ≥35%, hardness; HB135-179

Corrosion resistance and main use environment:

The corrosion resistance of Monel400 is generally better than nickel copper. It is more resistant to corrosion by reducing media than pure nickel, resistant to corrosion by oxidizing media than pure copper, and has very good corrosion resistance to sulfuric acid, phosphoric acid and carbon. In particular, it is resistant to hydrochloric acid corrosion, and also has excellent corrosion resistance to hot concentrated alkali. Monel400 alloy has excellent corrosion resistance in fluorine gas, hydrochloric acid, sulfuric acid, hydrofluoric acid and their derivatives. At the same time, it is more corrosion resistant than copper-based alloys in seawater.

Monel400 is a deformable nickel-copper nickel-based alloy, which has good seawater corrosion resistance and chemical corrosion resistance, and strong chloride stress corrosion cracking resistance. This alloy is one of the few alloys that can be used in fluoride. It has good resistance to oxide stress cracking corrosion in hydrofluoric acid and fluorine gas medium, such as sea water and salt water environment.

In medium concentration alkaline and salt solutions, Monel 400 also has very good corrosion resistance.

In a colder alkaline environment, the alloy is used in a weak acid environment such as sulfur and hydrogen fluoride.

Acid medium: Monel400 is corrosion resistant in sulfuric acid with a concentration of less than 85%. Monel400 is one of the few important materials that can withstand hydrofluoric acid.

Water corrosion: Under most water corrosion conditions, Monel400 alloy not only has excellent corrosion resistance, but also pitting corrosion and stress corrosion are rarely found, and the corrosion rate is less than 0.025mm/a.

High-temperature corrosion: The maximum temperature of Monel400 continuous working in air is generally around 600℃, and the corrosion rate in high-temperature steam is less than 0.026mm/a. Ammonia: Due to the high nickel content of Monel400 alloy, it can withstand corrosion under anhydrous ammonia and ammoniating conditions below 585℃.

Supporting welding materials and welding process: It is recommended to use AWS A5.14 welding wire ERNiCu-7 or AWS A5.11 welding rod EniCrCu-7 for welding of MONEL400 alloy. The welding material size is Φ2.4, 3.2, 4.0, and the place of origin is: American SMC and Germany Nickel, welding process and instructions are welcome to call for.

Stock situation: MONEL400 alloy plate stock size is 0.8mm-12mm, MONEL400 alloy bar stock size is Φ12mm-Φ220mm, pipe fittings and other products can be customized according to customer requirements. The material producing areas mainly include Japanese Metallurgy, American SMC, and German ThyssenKrupp VDM. Provide original material certificate, customs declaration and certificate of origin.

Application areas include: sulfuric acid and hydrofluoric acid equipment, marine heat exchangers, seawater desalination equipment, salt production equipment, marine and chemical processing equipment, propeller shafts and water pumps, gasoline and water tanks, etc.

| Product Name | Monel 400(UNS N04400) Alloy Seamless Tube |

| Type | Seamless |

| Shape | Square / Rectangular / Round |

| Standard | GB,AISI,ASTM,DIN,EN,JIS |

| Grade | Stainless steel 304 / 304L / 310S / 316L / 317L / 904L / 2205 / 2507 / 32760 / 253MA / 254Mo / S31803 / S32750 / S32205 etc |

| Monel 400 / Monel K-500 | |

| Inconel 600 / Inconel 601 / Inconel 625 / Inconel 617 / Inconel 690 / Inconel 718 / Inconel X-750 | |

| Incoloy A-286 / Incoloy 800 / Incoloy 800H / Incoloy 800HT | |

| Incoloy 825 / Incoloy 901 / Incoloy 925 / Incoloy 926 | |

| Nimonic 75 / Nimonic 80A / Nimonic 90 / Nimonic 105 / Nimonic 263 / Nimonic L-605 | |

| Hastelloy B / Hastelloy B-2 / Hastelloy B-3 / Hastelloy C / Hastelloy C-276 / Hastelloy C-22 | |

| Hastelloy C-4 / Hastelloy C-200 / Hastelloy G-35 / Hastelloy X / Hastelloy N | |

| Austenitic stainless steel 904L / XM-19 / 316Ti / 316LN / 371L / 310S / 253MA | |

| DP steel 254SMo / F50 / 2205 / 2507 / F55 / F60 / F61 / F65 | |

| PH stainless steel 15-5PH / 17-4PH / 17-7PH | |

| Out diameter | Seamless Pipe 6MM - 1174MM or customized |

| Thickness | Seamless Pipe 1mm - 80mm or customized |

| Max Length | Seamless Pipe 12000mm or customized |

| Finish | 2B, Pickling, polished, brushed, sandblast, BA, EP, |

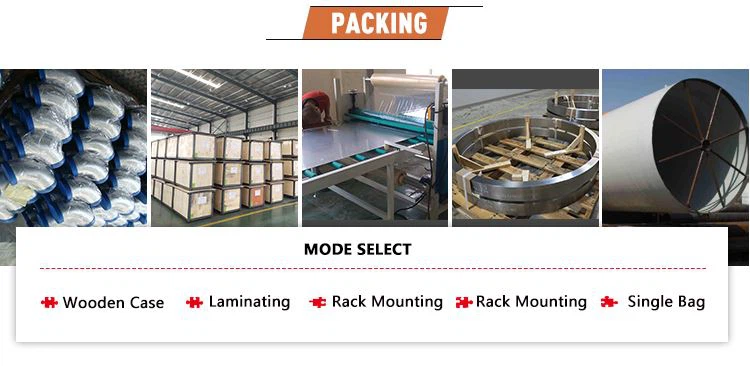

| Packing | waterproof polybag, wooden box, end cap, wooden crame/pallet |

| Inspection | TUV,SGS,BV,ABS,LR and so on |

| Application | Chemical, Pharmaceutical & Bio-Medical, Petrochemical & Refinery, Environmental, Food Processing, Aviation, Chemical Fertilizer, Sewage Disposal, Desalination, Waste Incineration etc. |

| Processing Service | Machining : Turning / Milling / Planing / Drilling / Boring / Grinding / Gear Cutting / CNC Machining |

| Deformation processing : Bending / Cutting / Rolling / Stamping | |

| Welded | |

| Forged | |

| Delivery Time | 7-40 days |

| Trade Term | FOB CIF CFR CIP DAP DDP EXW |

| Payment | T/T, L/C,D/A,D/P, Western Union,MoneyGram,According to customer requirements payments for offline orders. |

| Transportation | By air, by sea, by train, by truck |

| Sample | Free |

| Warranty | Trade assurance after sales service |