Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

Inconel 690 is an alloy mainly used for heat transfer tube materials of steam generators in pressurized water reactor nuclear power plants. It is the core technology of steam generators.

Inconel 690 alloy is an austenitic nickel-based corrosion resistant alloy containing 30% Cr. It not only has better resistance to stress corrosion cracking than Inconel 600, Inconel 800, and 304 stainless steel in chloride-containing solutions and sodium hydroxide solutions, but also has high strength, good metallurgical stability and excellent processing characteristics. Especially in various types of high temperature water, Inconel 690 alloy shows a low corrosion rate and excellent stress corrosion resistance. These properties are very suitable for nuclear waste treatment devices, steam generators, and nitric acid resistant parts.

Nickel-based alloy 690 chemical composition (mass percentage).

|

Ni

|

Cr

|

Fe

|

C

|

Al

|

Ti

|

Mn

|

Si

|

Cu

|

P

|

S

|

|

margin

|

30.39

|

8.88

|

0.023

|

0.22

|

0.26

|

0.23

|

0.07

|

0.02

|

0.006

|

0.002

|

The physical and mechanical properties of annealed 690 alloy.

|

Density

|

Melting

|

Young's modulus

|

Poisson's ratio

|

Yield strength

|

Tensile strength

|

Elongation

|

|

density

|

Melting point

|

Young's modulus

|

Poisson's ratio

|

Yield Strength

|

tensile strength

|

Elongation

|

|

8.19g/cm

|

1343-1377°C

|

211GPa

|

0.289

|

350MPa

|

700MPa

|

45%

|

Among the PWR nuclear power plant units already in operation in my country, only Qinshan Phase I uses 800 alloy, and Qinshan Phase II, Daya Bay and Lingao nuclear power plants all use 690 alloy as the steam generator heat transfer tube material. Most of the PWR nuclear power plants under construction and planning also use 690 alloy as the steam generator heat transfer tube material. However, the 690 alloy tubes used in PWR nuclear power plants that have been in operation in China are basically purchased from abroad. The major foreign companies that produce 690 alloy pipes include France's Valinox, Sweden's Sandvik and Japan's Sumitomo.

| Product Name | Inconel 690(UNS N06690) Nickel Alloy Seamless Pipe |

| Type | Seamless |

| Shape | Square / Rectangular / Round |

| Standard | GB,AISI,ASTM,DIN,EN,JIS |

| Grade | Stainless steel 304 / 304L / 310S / 316L / 317L / 904L / 2205 / 2507 / 32760 / 253MA / 254Mo / S31803 / S32750 / S32205 etc |

| Monel 400 / Monel K-500 | |

| Inconel 600 / Inconel 601 / Inconel 625 / Inconel 617 / Inconel 690 / Inconel 718 / Inconel X-750 | |

| Incoloy A-286 / Incoloy 800 / Incoloy 800H / Incoloy 800HT | |

| Incoloy 825 / Incoloy 901 / Incoloy 925 / Incoloy 926 | |

| Nimonic 75 / Nimonic 80A / Nimonic 90 / Nimonic 105 / Nimonic 263 / Nimonic L-605 | |

| Hastelloy B / Hastelloy B-2 / Hastelloy B-3 / Hastelloy C / Hastelloy C-276 / Hastelloy C-22 | |

| Hastelloy C-4 / Hastelloy C-200 / Hastelloy G-35 / Hastelloy X / Hastelloy N | |

| Austenitic stainless steel 904L / XM-19 / 316Ti / 316LN / 371L / 310S / 253MA | |

| DP steel 254SMo / F50 / 2205 / 2507 / F55 / F60 / F61 / F65 | |

| PH stainless steel 15-5PH / 17-4PH / 17-7PH | |

| Out diameter | Seamless Pipe 6MM - 1174MM or customized |

| Thickness | Seamless Pipe 1mm - 80mm or customized |

| Max Length | Seamless Pipe 12000mm or customized |

| Finish | 2B, Pickling, polished, brushed, sandblast, BA, EP, |

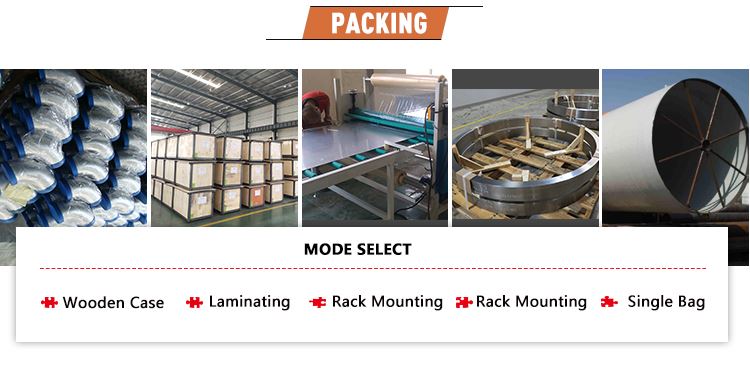

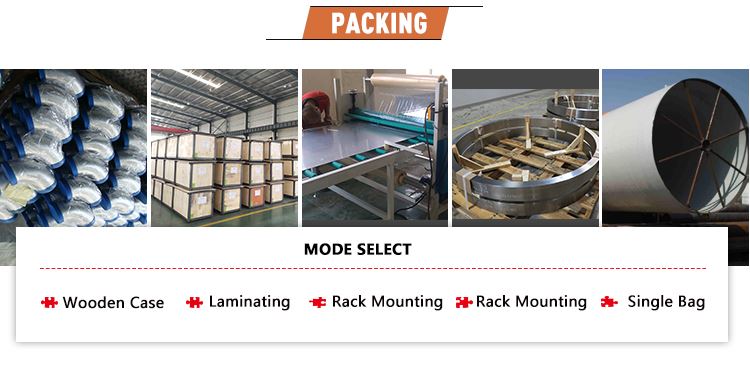

| Packing | waterproof polybag, wooden box, end cap, wooden crame/pallet |

| Inspection | TUV,SGS,BV,ABS,LR and so on |

| Application | Chemical, Pharmaceutical & Bio-Medical, Petrochemical & Refinery, Environmental, Food Processing, Aviation, Chemical Fertilizer, Sewage Disposal, Desalination, Waste Incineration etc. |

| Processing Service | Machining : Turning / Milling / Planing / Drilling / Boring / Grinding / Gear Cutting / CNC Machining |

| Deformation processing : Bending / Cutting / Rolling / Stamping | |

| Welded | |

| Forged | |

| Delivery Time | 7-40 days |

| Trade Term | FOB CIF CFR CIP DAP DDP EXW |

| Payment | T/T, L/C,D/A,D/P, Western Union,MoneyGram,According to customer requirements payments for offline orders. |

| Transportation | By air, by sea, by train, by truck |

| Sample | Free |

| Warranty | Trade assurance after sales service |