Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

Incoloy 901 has high yield strength and endurance strength below 650℃, good oxidation resistance below 760℃, and stable organization after long-term use.

Incoloy 901 is a relatively mature alloy developed in the early stage. It is widely used in the manufacture of rotating disc parts (turbine discs, compressor discs, journals, etc.), static structural parts, turbines for aviation and ground gas turbine engines operating below 650°C . Parts such as outer ring and fasteners.

Incoloy 901 alloy has high yield strength and endurance strength below 650℃, good oxidation resistance below 760℃, and stable organization after long-term use. Incoloy 901 is a relatively mature alloy developed in the early stage. It is widely used in the manufacture of rotating disc parts (turbine disc, compressor disc, journal, etc.), static structural parts, turbine Parts such as outer ring and fasteners.

|

C

|

Cr

|

Ni

|

Mo

|

Al

|

Ti

|

Fe

|

B

|

|

0.02~0.06

|

11.0~14.0

|

40.0~45.0

|

5.0~6.5

|

≤0.30

|

2.8~3.1

|

More than

|

0.01~0.02

|

|

Mn

|

Si

|

P

|

S

|

Cu

|

Bi

|

Pb

|

Ag

|

|

no greater than

|

|

|

|

|

|

|

|

|

0.50

|

0.40

|

0.020

|

0.008

|

0.20

|

0.0001

|

0.001

|

0.0005

|

1090℃±10℃, 2~3h, water cooling or oil cooling +775℃±5℃, 4h, air cooling +700~720℃, 24h, air cooling.

Incoloy 901 Can supply all kinds of disc forgings, rolled ring parts, bars and other forgings. The supply status can be delivered by heat treatment or without heat treatment.

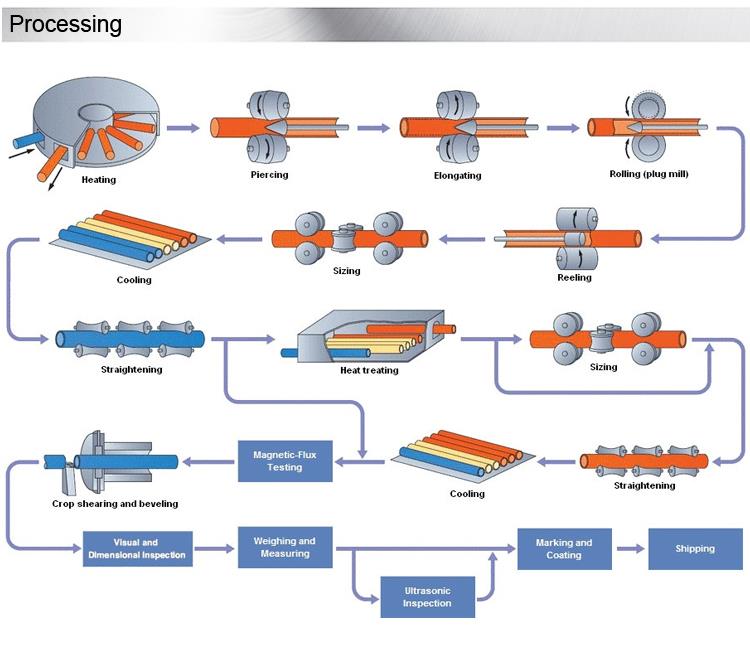

Incoloy 901 is produced by the double process of vacuum induction and vacuum arc remelting, or vacuum induction and electroslag remelting process.

Incoloy 901 is widely used in aero engines and ground gas turbines for rotating parts and fasteners that work below 650°C, and has a long service life. It has also been used in aero engines in China, and it is a mature alloy that has passed the test of use.

Alloy forging is advanced, if the process parameters are selected or operated improperly, its performance will show obvious directionality and may cause notch sensitivity, but as long as the process is strict, this phenomenon will not occur. The expansion coefficient of this alloy is close to that of ferritic heat-strength alloy steel, so that the two materials can be connected and there is no special requirement for the heat account.

FAQ:

| Product Name | Incoloy 901(UNS N09901)Seamless Pipes & Tubes |

| Type | Seamless |

| Shape | Square / Rectangular / Round |

| Standard | GB,AISI,ASTM,DIN,EN,JIS |

| Grade | Stainless steel 304 / 304L / 310S / 316L / 317L / 904L / 2205 / 2507 / 32760 / 253MA / 254Mo / S31803 / S32750 / S32205 etc |

| Monel 400 / Monel K-500 | |

| Inconel 600 / Inconel 601 / Inconel 625 / Inconel 617 / Inconel 690 / Inconel 718 / Inconel X-750 | |

| Incoloy A-286 / Incoloy 800 / Incoloy 800H / Incoloy 800HT | |

| Incoloy 825 / Incoloy 901 / Incoloy 925 / Incoloy 926 | |

| Nimonic 75 / Nimonic 80A / Nimonic 90 / Nimonic 105 / Nimonic 263 / Nimonic L-605 | |

| Hastelloy B / Hastelloy B-2 / Hastelloy B-3 / Hastelloy C / Hastelloy C-276 / Hastelloy C-22 | |

| Hastelloy C-4 / Hastelloy C-200 / Hastelloy G-35 / Hastelloy X / Hastelloy N | |

| Austenitic stainless steel 904L / XM-19 / 316Ti / 316LN / 311L / 310S / 253MA | |

| DP steel 254SMo / F50 / 2205 / 2507 / F55 / F60 / F61 / F65 | |

| PH stainless steel 15-5PH / 17-4PH / 17-7PH | |

| Out diameter | Seamless Pipe 6MM - 1174MM or customized |

| Thickness | Seamless Pipe 1mm - 80mm or customized |

| Max Length | Seamless Pipe 12000mm or customized |

| Finish | 2B, Pickling, polished, brushed, sandblast, BA, EP, |

| Packing | waterproof polybag, wooden box, end cap, wooden crame/pallet |

| Inspection | TUV,SGS,BV,ABS,LR and so on |

| Application | Chemical, Pharmaceutical & Bio-Medical, Petrochemical & Refinery, Environmental, Food Processing, Aviation, Chemical Fertilizer, Sewage Disposal, Desalination, Waste Incineration etc. |

| Processing Service | Machining : Turning / Milling / Planing / Drilling / Boring / Grinding / Gear Cutting / CNC Machining |

| Deformation processing : Bending / Cutting / Rolling / Stamping | |

| Welded | |

| Forged | |

| Delivery Time | 7-40 days |

| Trade Term | FOB CIF CFR CIP DAP DDP EXW |

| Payment | T/T, L/C,D/A,D/P, Western Union,MoneyGram,According to customer requirements payments for offline orders. |

| Transportation | By air, by sea, by train, by truck |

| Sample | Free |

| Warranty | Trade assurance after sales service |