Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

Incoloy 925 (UNS N09925) is a hardenable nickel-based alloy with added molybdenum, copper, titanium and aluminum. Incoloy 925 alloy has the same corrosion resistance as Incoloy 825 alloy, but obtains higher strength through age hardening. The combination of nickel and chromium has a protective effect in both oxidizing and reducing atmospheres. The high nickel content can also resist chloride ion stress corrosion cracking. Pitting and crevice corrosion resistance is also very good.

Incoloy 925 belongs to corrosion-resistant stainless steel

chemical composition%

% Ni Fe Cr C Mn Si P S Mo Cu Ti AI Nb

Minimum 42.0 remainder 19.5 25 1.5 1.9 0.15 0.1

Maximum 46.0 remaining 23.5 0.03 1.00 0.5 0.03 0.03 3.5 3.0 2.4 0.50 0.50

Physical properties

Melting point 1311-1366

Density g/cm 8.14

The minimum value of mechanical properties at room temperature

Typical mechanical properties Tensile strength Yield strength Elongation Brinell hardness combined

Solution treatment 650 295 30

Performance characteristics

Inconel 925 stainless steel is a kind of inconel life gold. It also possesses the excellent strength and corrosion resistance of Loinel 825. Especially for stress cracking and stress corrosion cracking in sulfide environment, it has good resistance.

Downhole and surface are components used in acidic environments (containing hydrogen sulfide). Such as crude oil and natural gas production.

Incoloy 925 has the following characteristics:

Has good mechanical strength and extensive corrosion resistance

Application area Application area:

Commonly used in the manufacture of parts and components on oil and gas drilling equipment

FAQ:

| Product Name | Incoloy 925 (UNS N09925) Seamless Pipes & Tubes |

| Type | Seamless |

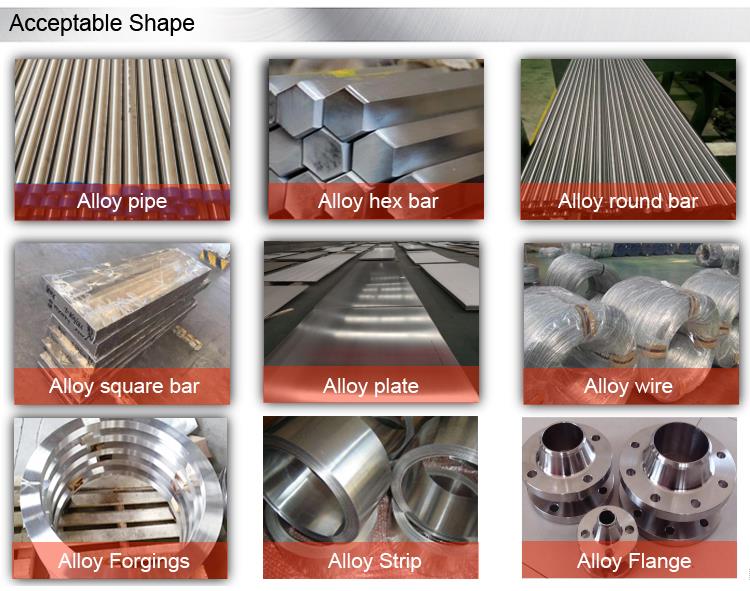

| Shape | Square / Rectangular / Round |

| Standard | GB,AISI,ASTM,DIN,EN,JIS |

| Grade | Stainless steel 304 / 304L / 310S / 316L / 317L / 904L / 2205 / 2507 / 32760 / 253MA / 254Mo / S31803 / S32750 / S32205 etc |

| Monel 400 / Monel K-500 | |

| Inconel 600 / Inconel 601 / Inconel 625 / Inconel 617 / Inconel 690 / Inconel 718 / Inconel X-750 | |

| Incoloy A-286 / Incoloy 800 / Incoloy 800H / Incoloy 800HT | |

| Incoloy 825 / Incoloy 901 / Incoloy 925 / Incoloy 926 | |

| Nimonic 75 / Nimonic 80A / Nimonic 90 / Nimonic 105 / Nimonic 263 / Nimonic L-605 | |

| Hastelloy B / Hastelloy B-2 / Hastelloy B-3 / Hastelloy C / Hastelloy C-276 / Hastelloy C-22 | |

| Hastelloy C-4 / Hastelloy C-200 / Hastelloy G-35 / Hastelloy X / Hastelloy N | |

| Austenitic stainless steel 904L / XM-19 / 316Ti / 316LN / 317L / 310S / 253MA | |

| DP steel 254SMo / F50 / 2205 / 2507 / F55 / F60 / F61 / F65 | |

| PH stainless steel 15-5PH / 17-4PH / 17-7PH | |

| Out diameter | Seamless Pipe 6MM - 1174MM or customized |

| Thickness | Seamless Pipe 1mm - 80mm or customized |

| Max Length | Seamless Pipe 12000mm or customized |

| Finish | 2B, Pickling, polished, brushed, sandblast, BA, EP, |

| Packing | waterproof polybag, wooden box, end cap, wooden crame/pallet |

| Inspection | TUV,SGS,BV,ABS,LR and so on |

| Application | Chemical, Pharmaceutical & Bio-Medical, Petrochemical & Refinery, Environmental, Food Processing, Aviation, Chemical Fertilizer, Sewage Disposal, Desalination, Waste Incineration etc. |

| Processing Service | Machining : Turning / Milling / Planing / Drilling / Boring / Grinding / Gear Cutting / CNC Machining |

| Deformation processing : Bending / Cutting / Rolling / Stamping | |

| Welded | |

| Forged | |

| Delivery Time | 7-40 days |

| Trade Term | FOB CIF CFR CIP DAP DDP EXW |

| Payment | T/T, L/C,D/A,D/P, Western Union,MoneyGram,According to customer requirements payments for offline orders. |

| Transportation | By air, by sea, by train, by truck |

| Sample | Free |

| Warranty | Trade assurance after sales service |