Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

Super Duplex 2507 flanges are made of a stainless steel alloy containing 25% chromium, 4% molybdenum, and 7% nickel. Duplex 2507 is known for its high strength and excellent localized corrosion resistance to chloride. This alloy is widely used for its yield strength which is twice that of annealed austenitic stainless steels, like 304 and 316 stainless.

Super Duplex 2507 Strength

Offering high impact and mechanical strength, Super Duplex 2507 flanges can be used at temperatures up to 570°F before you will see a reduction in strength.

Super Duplex Corrosion Resistance

Chloride corrosion resistance is one of the key attributes of Super Duplex 2507 flanges due to its specialty metal makeup. The high molybdenum, chromium and nitrogen content of Super Duplex provides these flanges excellent resistance to chloride corrosion such as pitting and crevice attack, while its ferritic structure makes it very resistant to stress corrosion cracking in warm chloride environments. Super Duplex 2507 flanges also provide uniform corrosion protection from organic acids such as formic and acetic acid, plus inorganic acids, especially those containing chlorides. In addition, 2507 flanges are highly resistant to carbide-related intergranular corrosion due to their low carbon content (0.020% in weight).

Specification of product

|

Product Name |

Super Duplex 2507 Pipe Flanges |

|

|

Standard: ASME B16.47 SER.A (MSS SP44) |

|

Material Grades |

Stainless Steel:ASTM A182-F304, F304L, F304H, F316, F316L, F321, F321H, |

|

|

Raw Material Test Report |

|

|

Ultrasonic Test, Radiographic Examination, PMI Test, Penetration Test, Dimension Examination, Surface Examination, Hardness Test, Metallographic Examination,Intergranular Corrosion Test, Grain Size Test, Mechanical Property Test, Tension Test, Bending Test, Impact Test. |

|

Price term |

EXW factory, FOB, C&F and CIF |

|

Payment term |

T/T, L/C, West Union, Money Gram and etc |

|

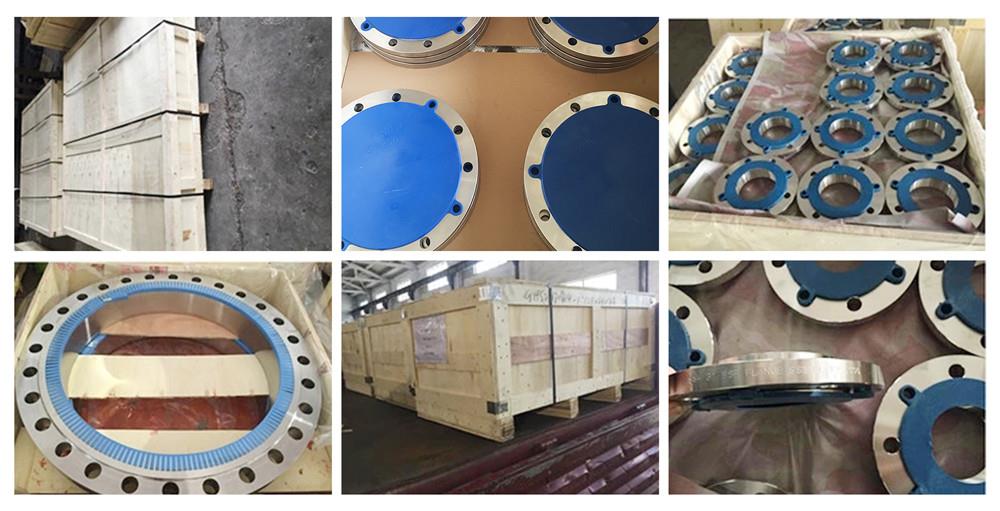

Package |

Standard export wooden case or as per requested |

Key Benefits

●Very high resistance to pitting, erosion and crevice corrosion, as well as corrosion fatigue

●Excellent resistance to stress corrosion cracking (SCC) in chloride environments

●High resistance to general corrosion in acids

●Very high mechanical strength

●Good weldability: Can be readily joined to itself or other materials

●High thermal conductivity

●Low coefficient of thermal expansion, close to that of carbon steel.

Production process

1.22 Years Of Manufacturing Experience

2.We offers a commendable range of Stainless Steel Pipe, Fittings, Flanges with competitive price.

3.Customizable, International Standards

4.Strict Testing Process, Quality Assurance

5.7*24H Online service.

Fast Delivery:7-15days