Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

Stainless Steel Forged Flange Can be defined as a metal disc, Installed at the back of a tube valve or any other object. It allows simple fitting and replacement of a piping system.The undergo the forging process where by mechanical, energy is applied to a steel flange, to chage its shape when in a solid stage.

Forged Flange Applications

Forged flanges are used as a connection component for pipes, valves, pumps and other equipment to form a pipework system. They provide easy access for cleaning, inspection, modification or repairs. Flanges are usually welded onto pipes or screwed onto a threaded pipe end and then joined with bolts to make the connection.

Standard Specification for Forged Flanges

|

Dimensions |

Duplex Stainless Steel Forged Steel Flange is a variant of stainless steel in which high levels of chromium, nickel and molybdenum contribute to improved pitting resistance. The presence of nitrogen contributes to tissue hardening, increasing yield strength and ultimate strength without altering toughness. The Duplex Stainless Steel Forged Steel Flanges consists of ferrite and austenitic stainless steel grains. Embedded in the same material, it is generally harder than ferritic steel and nearly twice as strong as austenitic steel. It also has good corrosion resistance, can successfully combat intergranular corrosion and prevent stress corrosion cracking in chloride and sulfide environments. So this product has advantages of long service life and low maintenance cost.

Features 1.Raw material from reputed millsto guarantee the chemical composition and mechanical properties; 2.Can be manufactured and supplied in a variety of sizes and pressure ratings to meet project specific requirements of our customers.Customized products available;

3.All flanges produced from forged raw material,which result to better grain size and microstructure.

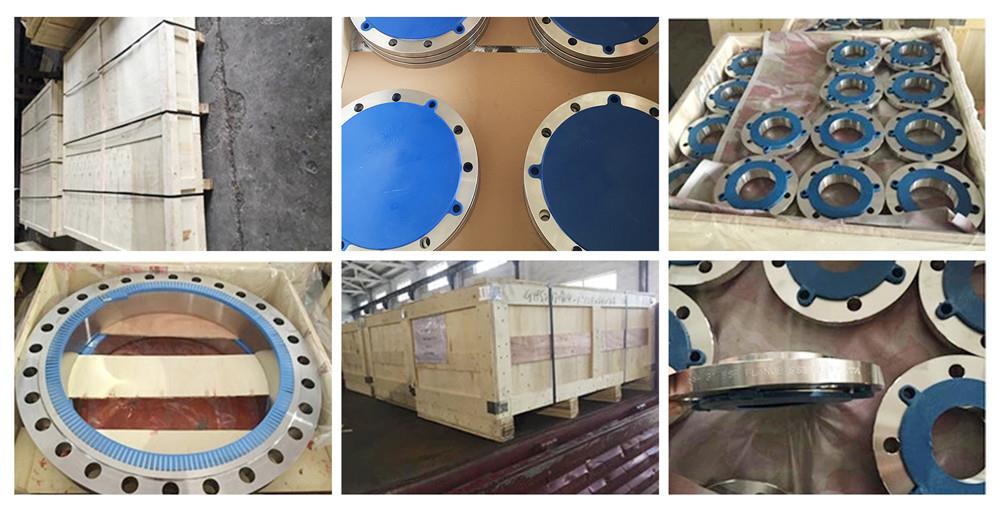

Product Display

Production Process

Why Choose Ronsco 1.22 Years Of Manufacturing Experience

2.We offers a commendable range of Stainless Steel Pipe, Fittings, Flanges with competitive price 6.Fast Delivery:7-15days

Packaging And Shipping

|

|||||||||||||||||||||||||||||||||||||

|

SIze |

1/2, 15NB,TO 48 (1200NB) |

|||||||||||||||||||||||||||||||||||||

|

Class |

150lbs,300lbs,600lbs,900lbs,1500lbs,2500lbs |

|||||||||||||||||||||||||||||||||||||

|

DIN |

DIN2527,2566,2573,2641,2642,2655,2627. |

|||||||||||||||||||||||||||||||||||||

|

BS |

BS54504,BS4504,BS1560,BS10 |

|||||||||||||||||||||||||||||||||||||

|

Flange face type |

Flate face,Raised Face,Ring Type Joint |

|||||||||||||||||||||||||||||||||||||

|

Forged Flange |

Forged Steel Flange |

|||||||||||||||||||||||||||||||||||||

|

ANSI B16.5 Forged Flanges |

Forged Flange Dimensions |

|||||||||||||||||||||||||||||||||||||

|

ASME B16.5 Forged Flanges |

ANSI B16.5 Class 150 Forged Flanges |

|||||||||||||||||||||||||||||||||||||

|

Stainless Steel Forged Flanges Suppliers |

SS Forged Flanges |

|||||||||||||||||||||||||||||||||||||

|

ANSI B16.5 Class 150 Forged Flanges Stockholder |

ANSI 150 Forged Flanges Distributors |

|||||||||||||||||||||||||||||||||||||

|

ASTM A182 Stainless Steel Forged Flanges |

Duplex Steel Forged Flanges |

|||||||||||||||||||||||||||||||||||||

|

Super Duplex Steel Forged Flanges |

High Nickel Alloy Forged Flanges |

|||||||||||||||||||||||||||||||||||||

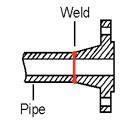

Weld Neck Ring Flange (WNRF)

Weld neck flanges are circumferentially welded at the neck where the integrity of the butt welded area can be easily examined by radiography. The bores of both pipe and flange match, which reduces turbulence and erosion inside the pipeline. The weld neck is therefore durable in critical applications.

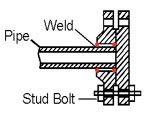

Slip-On Ring Flange (SORF)

Slip-on flanges are fitted over the pipe and then fillet welded. Slip-on flanges are easy to use in fabricated applications.

Blind Ring Flange (BLRF)

Blind flanges are used to blank off pipelines, valves and pumps. They can also be used as an inspection cover. It is sometimes referred to as a blanking flange.

Socket Weld Ring Flange (SWRF)

Socket weld ring flanges are counter-bored to accept the pipe before being fillet welded. The bore of the pipe and flange are both the same to provide good flow characteristics.

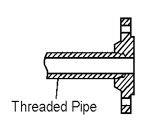

Threaded Ring Flange

Threaded flange are referred to as either threaded or screwed. They are used to connect other threaded components in low pressure, non-critical applications. No welding is required.

Lap Joint Ring Flange (LJRF)

Lap joint flanges are always used with either a stub end or taft which is butt welded to the pipe with the flange loose behind it. This means the stub end or taft always makes the face. A lap joint is used in low pressure applications because it is easily assembled and aligned. To reduce costs, these flanges are supplied without a hub.

Ring Type Joint Flange (RTJF)

Ring type joint flanges are used to ensure a leak proof flange connection at high pressures. A metal ring is compressed into a hexagonal groove on the face of the flange to make the seal. This jointing method can be employed on Weld Neck, Slip-on and Blind Flanges.

ASME16.5 Forged Flanges Test Certificates:

Manufacturer Test Certificate as per EN 10204/3.1B, Raw Materials Certificate. 100% Radiography Test Report.Third Party inspection Reports as client specification.

Ronsco provides high quality products with third party inspection also. The inspection agency can be nominated by clients.

Why Choose Ronsco:

1.22 Years Of Manufacturing Experience

2.We offers a commendable range of Stainless Steel Pipe, Fittings, Flanges with competitive price.

3.Customizable, International Standards

4.Strict Testing Process, Quality Assurance

5.7*24H Online service.

6.Fast Delivery:7-15days

Ronsco have Skilled staff to maintain the quality of products throughout the manufacturing process from selection of raw material to processing, marking, packaging, storage, and transportation. Our Forged Steel Flange are 100% inspected before being packed and dispatched all our materials are tested to International standards. Sometimes we also accept Third Party Inspection appointed by our clients.