Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

Technical Data Sheet of Inconel 625 (UNS N06625/W.Nr.2.4856) Welded Pipe

| Product Name | Inconel 625 (UNS N06625/W.Nr.2.4856) Welded Pipe |

| Similar Grades | Inconel 600, 2.4816, NiCr15Fe, NA 14, NAS 600/NCF 600 |

| Type | Welded |

| Shape | Square / Rectangular / Round |

| Standard | GB,AISI,ASTM,DIN,EN,JIS |

| Grade | Stainless steel 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 32760 / 253MA / 254SMo / XM-19 / S31803 / S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65 etc |

| Monel 400 / Monel K-500 | |

| Inconel 600 / Inconel 601 / Inconel 625 / Inconel 617 / Inconel 690 / Inconel 718 / Inconel X-750 | |

| Incoloy A-286 / Incoloy 800 / Incoloy 800H / Incoloy 800HT | |

| Incoloy 825 / Incoloy 901 / Incoloy 925 / Incoloy 926 | |

| Nimonic 75 / Nimonic 80A / Nimonic 90 / Nimonic 105 / Nimonic C263 / L-605 | |

| Hastelloy B / Hastelloy B-2 / Hastelloy B-3 / Hastelloy C / Hastelloy C-276 / Hastelloy C-22 | |

| Hastelloy C-4 / Hastelloy C-2000 / Hastelloy G-35 / Hastelloy X / Hastelloy N | |

| PH stainless steel 15-5PH / 17-4PH / 17-7PH | |

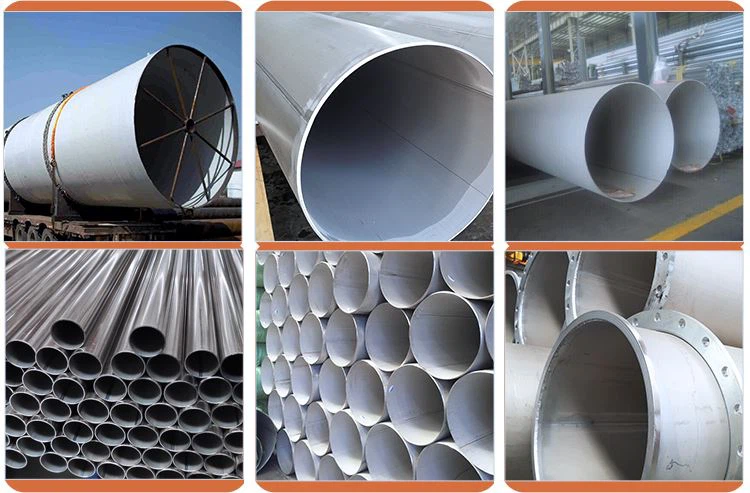

| Out diameter | Welded Pipe 1.9mm - 5000mm or customized |

| Thickness | Welded Pipe 0.5mm - 80mm or customized |

| Max Length | Welded Pipe 50000mm or customized |

| Finish | 2B, Pickling, Polished, Brushed, Sandblast, BA, EP |

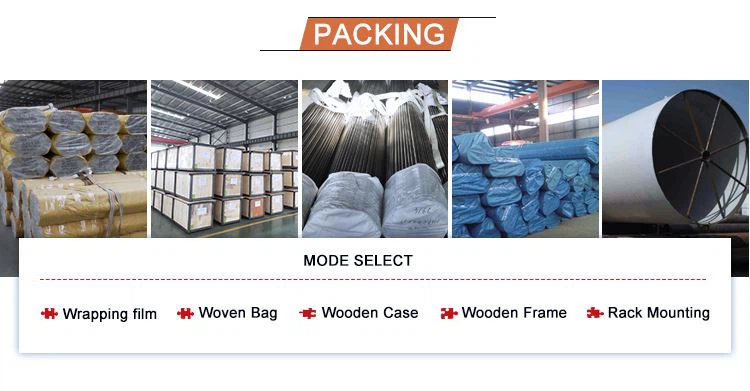

| Packing | Waterproof polybag, wooden box, end cap, wooden crame/pallet |

| Inspection | TUV,SGS,BV,ABS,LR and so on |

| Application | Chemical, Pharmaceutical & Bio-Medical, Petrochemical & Refinery, Environmental, Food Processing, Aviation, Chemical Fertilizer, Sewage Disposal, Desalination, Waste Incineration etc. |

| Processing Service | Machining : Turning / Milling / Planing / Drilling / Boring / Grinding / Gear Cutting / CNC Machining |

| Deformation processing : Bending / Cutting / Rolling / Stamping | |

| Welded | |

| Forged | |

| Delivery Time | 7-40 days |

| Trade Term | FOB CIF CFR CIP DAP DDP EXW |

| Payment | T/T, L/C,D/A,D/P, Western Union,MoneyGram,According to customer requirements payments for offline orders. |

| Transportation | By air, by sea, by train, by truck |

| Sample | Free |

| Warranty | Trade assurance after sales service |

1.Over 20 years of production experience.

2.Over 20000 tons of production capacity.

3.Over 2000 tons in regular stock.

4.Many imported international first-class processing equipment.

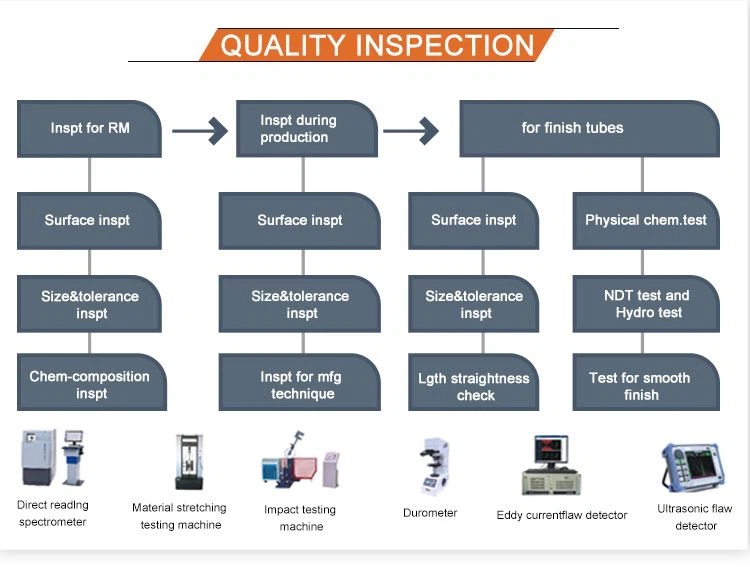

5.Provide BV / SGS supervision for the whole production process.

For More Information About Inconel 625 (UNS N06625/W.Nr.2.4856) Welded Pipe, please call +86 17708476248 or Send an Email to [marketing@ronsteel.com]