Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

Inconel 625 demonstrates an excellent combination of corrosion resistance and high strength. Due to the high nickel content, alloy 625 is immune to chloride-induced stress corrosion cracking. It also has good resistance to pitting and crevice corrosion. and shows good resistance to aqueous corrosion, but is relatively moderate compared to other more capable corrosion-resistant alloys.

They are available in a wide range of formats including wire, plate, sheet, strip, pipe, fittings, bar, flanges, and so on.

Chemical component:

|

Inconel 625 UNSN06625

|

|

| Grade | Inconel 625 UNSN06625 |

| Diameter Of Alloy Pipe | Hot Rolled: Φ8-38mm |

| Forging: Φ38-350mm | |

| Cold Rolled: ≤50mm | |

| Standard | ASTM AMSE YB HB BJB GB etc |

| Length | As Required |

| Surface | Black or Bright |

| Manufacture Technology | Hot Rolled, Forging, Cold Rolled |

| Package | wooden boxes package, PVC package, and another package |

|

Grade

|

Tensile Strength

|

Yield Strength

|

Ductility

|

HRB

|

|

UNS N06600(Inconel600)

|

552

|

241

|

30

|

-

|

|

UNS N06601(Inconel601)

|

552

|

207

|

30

|

-

|

|

UNS N06625(Inconel625)

|

|

|||

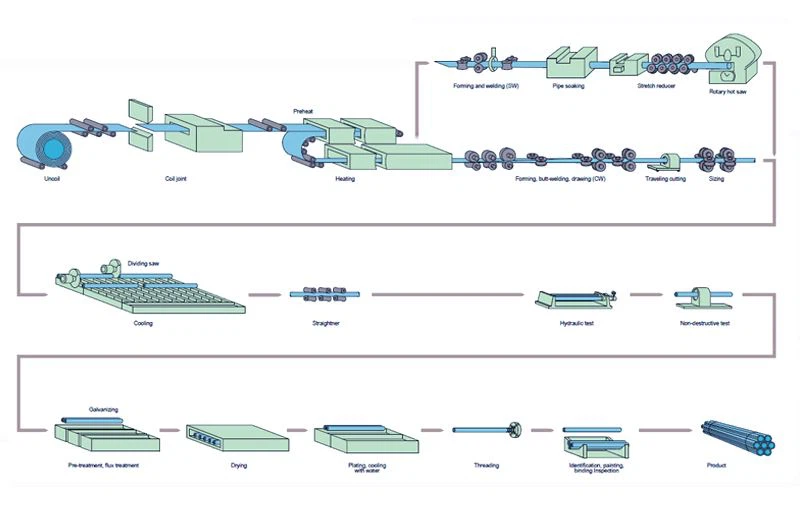

Production Processing:

Pipes for production and transportation of oil and gas

Structural and mechanical components

Desalination equipment

Heat exchangers

Cooling pipes

1. Compared with the same industry, due to our more modern and more efficient equipment and 22 years of production experience, the delivery time can be greatly shortened and the cost can be better saved.

2.More modern welding equipment and technology

3. Our average delivery time is 10-15 days. Annual production: 800,000 tons

4. Research and development(R&D):9% of the company's full-year net profit will be directly used for product development,

5. With 10 engineers with more than 15 years of R&D experience, new products are launched every 6 months.