Phone

+86-731-82250427

Address

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China.

|

253MA (UNS S30815, WNR 1.4835) is a kind of heat resistant stainless steel developed on the basis of 21cr-11ni stainless steel by alloying rare earth elements CE and CN. Generally, 253MA is austenite. Due to the interaction of rare earth elements and silicon, the material still has good oxidation resistance at 1150 ℃.

However, the existence of cyanide, carbon, rare earth elements and alkali metal oxides makes 253MA have the same stress rupture strength as Ni based alloy. Therefore, 253MA can replace the expensive nickel base alloy, and can be widely used in high temperature parts with working temperature above 900 ℃ and pressure bearing occasions below 900 ℃. |

|||||||||||

| 253MA Genenal Introduction | |||||||||||

| 253 MA is a stainless steel with excellent oxidation and creep resistance in cyclic conditions that is best employed in temperatures up to 1150 °C/2100 °F. There is a slight susceptibility to embrittlement during continuous operation at 600–850 °C/1110–1560 °F. | |||||||||||

| Chemical Composition: | |||||||||||

| Content | C | Si | Mn | S | Ni | Cr | P | Mo | Cu | Fe | Ce |

| Min | 0.05 | 1.40 |

|

|

10.00 | 20.00 |

|

|

|

Balance | 0.03 |

| Max | 0.10 | 2.00 | 0.80 | 0.03 | 12.00 | 22.00 | 0.040 |

|

|

0.08 | |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Forms & Specifications | |||||||||||

|

Bar & Profile: ASTM A276/ASME SA276 Thick Plate, Sheet & Strip: ASTM A240/A480/A167/ASME SA240, Seamless pipe/tube: ASTM A312/A213/ASME A312, ASTM A213/ASME SA213, ASTM A269/ASME SA269, Welded nominal pipe: ASTM A312/ASME A312, , ASTM A269/ASME SA269, ASTM A249/ASME SA249, ASTM A409/ASME SA409 Pipe fittings: ASTM A403 Forgings: ASTM A182 |

|||||||||||

| Physical Properties | Application: | ||||||||||

|

Density:8 g/cm³ Melting Range:1371-1432 ⁰C Poisson's Ratio:0.31 High creep strength. Very good resistance to isothermal and, particularly, cyclic oxidation. Good structural stability at high temperatures. Good weldability. Maximum operating temperature is approx. 1150°C (2100°F) |

Oil industry equipment Conveyor belts Refractory anchors Expansion bellows Radiant tubes, tube shields, and valves and flanges Rotary kilns Exhaust manifolds Power generation applications Cyclone dip tubes Impact separators Bell furnaces and muffle furnaces Automotive components Heat treatment trays Dampers Recuperator tubes for the steel industry Large-scale bakery ovens |

||||||||||

| Typical Mechanical Properties: | |||||||||||

| Product |

|

Yield Strength 0.2% min. (ksi) |

Tensile Strength min. (ksi) |

||||||||

| Sheet & Plate | ASTM A240 | 45.00 | 87.00 | ||||||||

| Seamless Tube & Pipe | ASTM A213 | 45.00 | 87.00 | ||||||||

| Seamless/Wedled Tube & Pipe | ASTM A312 | 45.00 | 87.00 | ||||||||

| Wedled Tube | ASTM A249 | 45.00 | 87.00 | ||||||||

Data Sheet of

| Product Name |

253MA (UNS S30815, WNR 1.4835) Stainless Steel Seamless Pipe |

| Type | Seamless / Welded |

| Shape | Square / Rectangular / Round |

| Standard | GB,AISI,ASTM,DIN,EN,JIS |

| Grade | Stainless steel 304 / 304L / 310S / 316L / 317L / 904L / 2205 / 2507 / 32760 / 253MA / 254Mo / S31803 / S32750 / S32205 etc |

| Monel 400 / Monel K-500 | |

| Inconel 600 / Inconel 601 / Inconel 625 / Inconel 617 / Inconel 690 / Inconel 718 / Inconel X-750 | |

| Incoloy A-286 / Incoloy 800 / Incoloy 800H / Incoloy 800HT | |

| Incoloy 825 / Incoloy 901 / Incoloy 925 / Incoloy 926 | |

| Nimonic 75 / Nimonic 80A / Nimonic 90 / Nimonic 105 / Nimonic 263 / Nimonic L-605 | |

| Hastelloy B / Hastelloy B-2 / Hastelloy B-3 / Hastelloy C / Hastelloy C-276 / Hastelloy C-22 | |

| Hastelloy C-4 / Hastelloy C-200 / Hastelloy G-35 / Hastelloy X / Hastelloy N | |

| Austenitic stainless steel 904L / XM-19 / 316Ti / 316LN / 371L / 310S / 253MA | |

| DP steel 254SMo / F50 / 2205 / 2507 / F55 / F60 / F61 / F65 | |

| PH stainless steel 15-5PH / 17-4PH / 17-7PH | |

| Out diameter | Welded Pipe 1.9mm - 5000mm or customized |

| Thickness | Welded Pipe 0.5mm - 80mm or customized |

| Max Length | Welded Pipe 50000mm or customized |

| Finish | 2B, Pickling, polished, brushed, sandblast, BA, EP, |

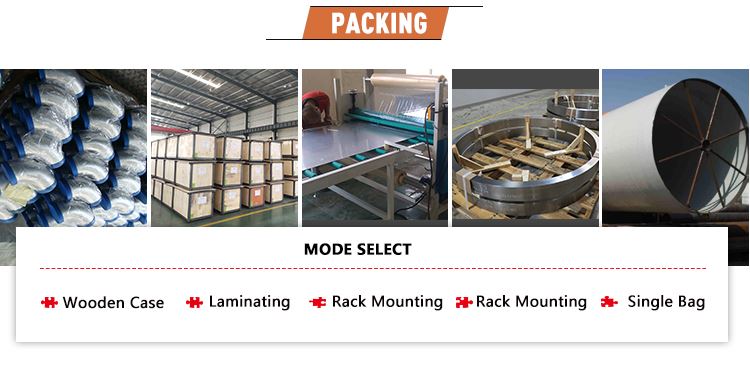

| Packing | waterproof polybag, wooden box, end cap, wooden crame/pallet |

| Inspection | TUV,SGS,BV,ABS,LR and so on |

| Application | Chemical, Pharmaceutical & Bio-Medical, Petrochemical & Refinery, Environmental, Food Processing, Aviation, Chemical Fertilizer, Sewage Disposal, Desalination, Waste Incineration etc. |

| Processing Service | Machining : Turning / Milling / Planing / Drilling / Boring / Grinding / Gear Cutting / CNC Machining |

| Deformation processing : Bending / Cutting / Rolling / Stamping | |

| Welded | |

| Forged | |

| Delivery Time | 7-40 days |

| Trade Term | FOB CIF CFR CIP DAP DDP EXW |

| Payment | T/T, L/C,D/A,D/P, Western Union,MoneyGram,According to customer requirements payments for offline orders. |

| Transportation | By air, by sea, by train, by truck |

| Sample | Free |

| Warranty | Trade assurance after sales service |